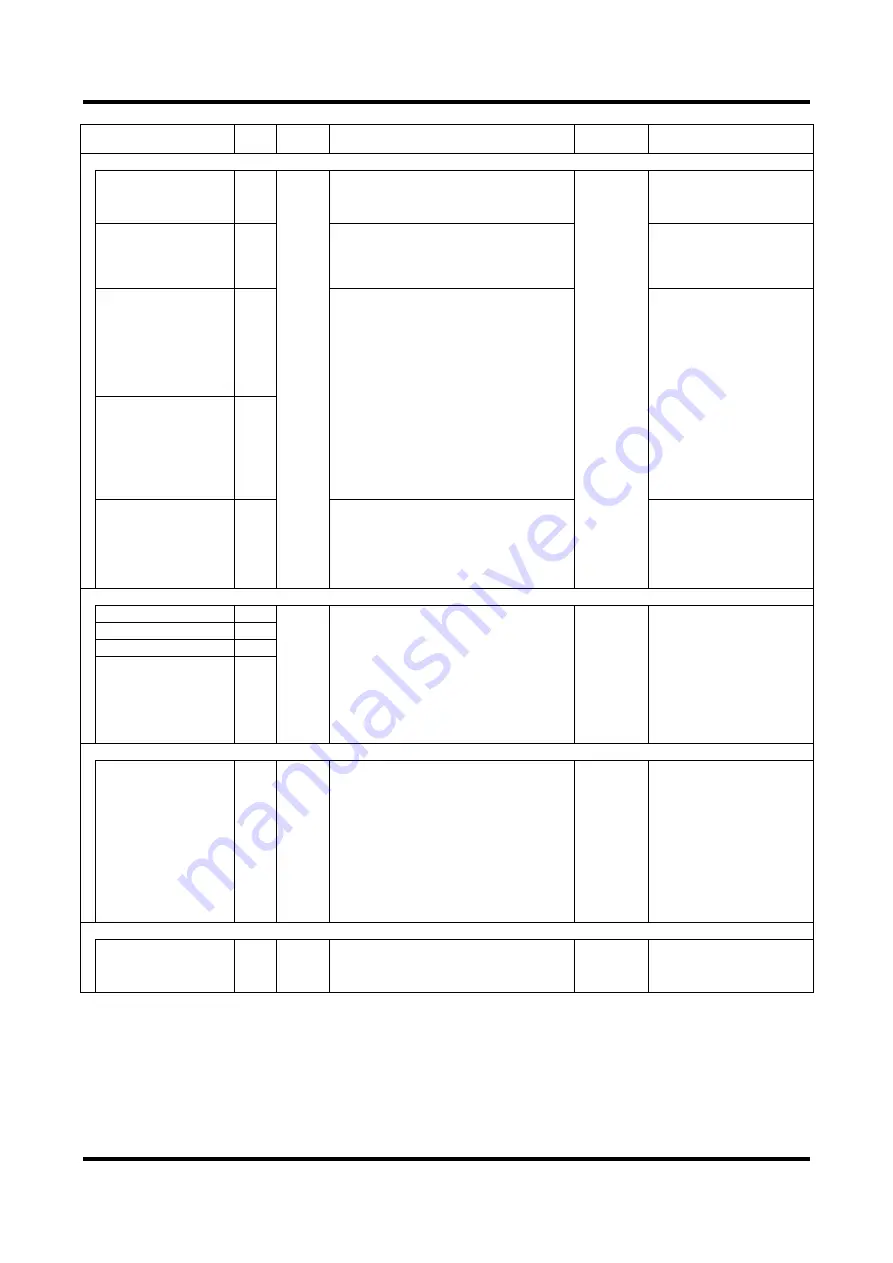

Appendix 3-2

TI71M01D06-01EN 3rd Edition: 2012.12.01

Name

Error

code

Recovery

Cause and condition detected

Action taken

at occurrence

Countermeasure

ABS encoder error

Excessive detection error

14.1

Not

possible

Abnormal absolute position signal was detected.

Inappropriate configuration (matching with motor)

Initial

processing

not completed

Execute the same

countermeasure for the error

14.3.

Correct configuration.

Excessive velocity at

detection

14.2

Motor moves when the power was turned on.

Abnormal resolver signal was detected.

Turn on the power while motor

is stopped.

Execute the same

countermeasure for the error

14.3.

SIG0 1X signal error

14.3

Abnormal resolver signal was detected.

Contact failure or damage of connector

Breaking of wire

Irruption of noise into encoder/resolver cable

Malfunction of motor

Malfunction of drive

Repair or replacement of

connector

Replacement of cable

Denoising or re-configuration

of wiring upon checking

source of noise

Put apart encoder-resolver

cable from electric power line

or high frequency line

Change of grounding of shield

Shortest encoder cable

Note: Be careful not to deforming

or damaging contact section

by tester equipment when

checking conduction of cable.

Replacement of motor

Replacement of drive

SIG0 NX signal error

14.4

Linear coordinate range

error

14.5

Motor position when the power is turned on was

out of coordination range set by #116, Limit of

absolute linear coordination 1 and #117, Limit of

absolute linear coordination 2

Re-set motor position when

the power is turn on so that it

can be within the coordination

range.

Change value(s) of limit of

absolute linear coordination

range.

Encoder error

SIG0 edge disengaged

15.1

Not

possible

An error was detected in an encoder/resolver

signal.

Contact failure or breakdown of a connector

Cable disconnection

Noise is generated in an encoder/resolver cable.

A problem inside the motor

A problem in the drive

* Check the conductivity of the cable by using a

tester. The contact area must not be deformed

or damaged.

Servo OFF

Check the connector section,

repair or replace if necessary.

Replace the cable.

Eliminate the noise

generating source, and

review the wiring route.

Replace the motor unit.

Replace the drive.

SIG1 edge disengaged

15.2

SIG0 cycle error

15.3

SIG1 cycle error

15.4

Coordinate system error A

Eccentric compensation

error

16.1

Not

possible

It was detected that the slit plate deviated from the

center and exceeded the allowable eccentric

volume in a DM series motor unit (except

DM1B-004/006, DM1C-004).

A moment load was applied to the rotation

section.

A support and cable made contact with the

hollow hole and therefore force was applied.

A substantial impact was applied to the motor.

An abnormal encoder signal was generated.

* A low velocity (0.05rps or less) was used for

detection.

Error setup

register 1

dependent,

bits 11 to 8

Remove the load, and also

remove the one that is giving

force.

Adjust the support and cable

so that they are not in contact

with the hollow hole.

Repair the motor unit if an

error occurs while in the

no-load state.

Check the items pertaining to

the encoder errors.

Coordinate system error B

Outside of command

coordinate area

17.2

Possible

The setup value to be used for coordinate system

operation (coordinate value setting) was less than

0 or more than the scaling command unit value

when the rotation coordinate system was used.

None in

particular