Appendix 3-3

TI71M01D06-01EN 3rd Edition: 2012.12.01

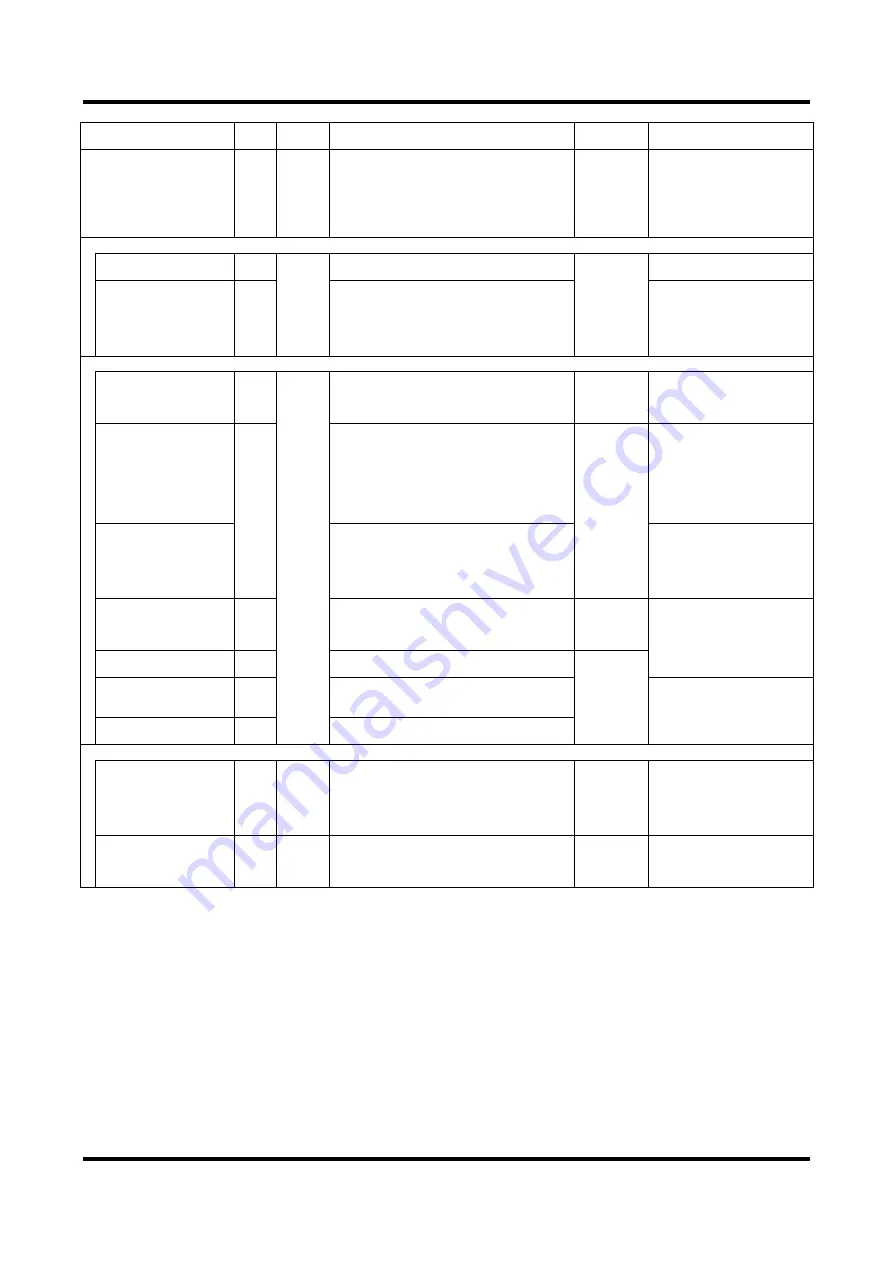

Name

Error

code

Recovery

Cause and condition detected

Action taken

at occurrence

Countermeasure

Monitor pulse error

18.0

Not

possible

Attempted to generate a pulse of 3MHz or more,

which exceeded an allowable monitor pulse output.

The motor overran.

Resonating and hunting.

Error setup

register 2

dependent,

bits 11 to 8

Check the wiring of the motor

cable and encoder cable.

Take an action against

resonance, and set an

appropriate adjustment value.

Set the scaling data to an

appropriate value.

Tandem error

Slave drive error

19.1

Possible

The master has detected an error in the slave.

Error setup

register 1

dependent,

bits 11 to 8

Remove the cause of the

abnormality on the slave side.

Tandem communication

error

19.2

Tandem communication abnormality has occurred

due to noise.

Check the connection status

of the communication cable.

Anti-noise in the

communication cable.

Remov the cause of the

noise.

Power module error

Over-voltage

20.1

Possible

Over-voltage level

main line voltage value

Servo OFF

Regeneration

error output

Check the main power supply

voltage level.

Verify that the motor is not

rotated by an external force.

IPM

fault

20.2

Temperature: 150

C or more

Control current: 12.5V or less

Over-current:

27A or more at 500W, 5

s

54A or more at 2kW, 5

s

Output short-circuited

With 1msec chattering process

Servo OFF

High ambient temperature

and high current duty

The GND of the motor cable

is wrongly wired to one of

phase A, B or C.

Verify that the motor is not

rotated at a high velocity by

an external force.

Current transformer

detection

Detection level: 15A at 500 W, 1

s

45A at 2kW, 1

s

With 1msec chattering process

The GND of the motor cable

is wrongly wired to one of

phase A, B or C.

Verify that the motor is not

rotated at a high velocity by

an external force.

Low

voltage

20.3

Low voltage (servo OFF) level

main line voltage

value < low voltage level

Error setup

register 1

dependent,

bits 7 to 4

Check the main power supply

voltage level.

Low voltage (servo OFF

level)

20.4

Main line voltage value < low voltage (servo OFF)

level

Servo OFF

Phases A and B actual

current monitoring

20.5

Phases A and B actual current vector lengths (after

bandwidth 10 Hz filter processing) exceeded 110%

of the maximum motor current.

It is necessary to repair the

drive board.

Error monitoring amplifier

constant substrate

20.6

Error was detected on the control board amplifier

constant substrate.

Main power supply error

Main power supply error

21.0

Possible

XMPSIG output threshold: 143VAC

XMPSIG from the power module maintained the

OFF state exceeding the value set up in system

setup register 1.

Error setup

register 1

dependent,

bits 3 to 0

Check the main power supply

voltage level.

The main power supply is

momentary shut down.

Fluctuations of the main

power supply are substantial.

Main power supply errorAC

(Open-Phase or Low

Voltage)

21.1

Possible

AC Main Power was detected open-phase or low

voltage over 1 second.

Error setup

register 1

dependent,

bits 2 to 0

Check wiring of every phase of

AC Main Power and the AC Main

Power Voltage.