7-15

TI71M01D06-01EN 3rd Edition: 2012.12.01

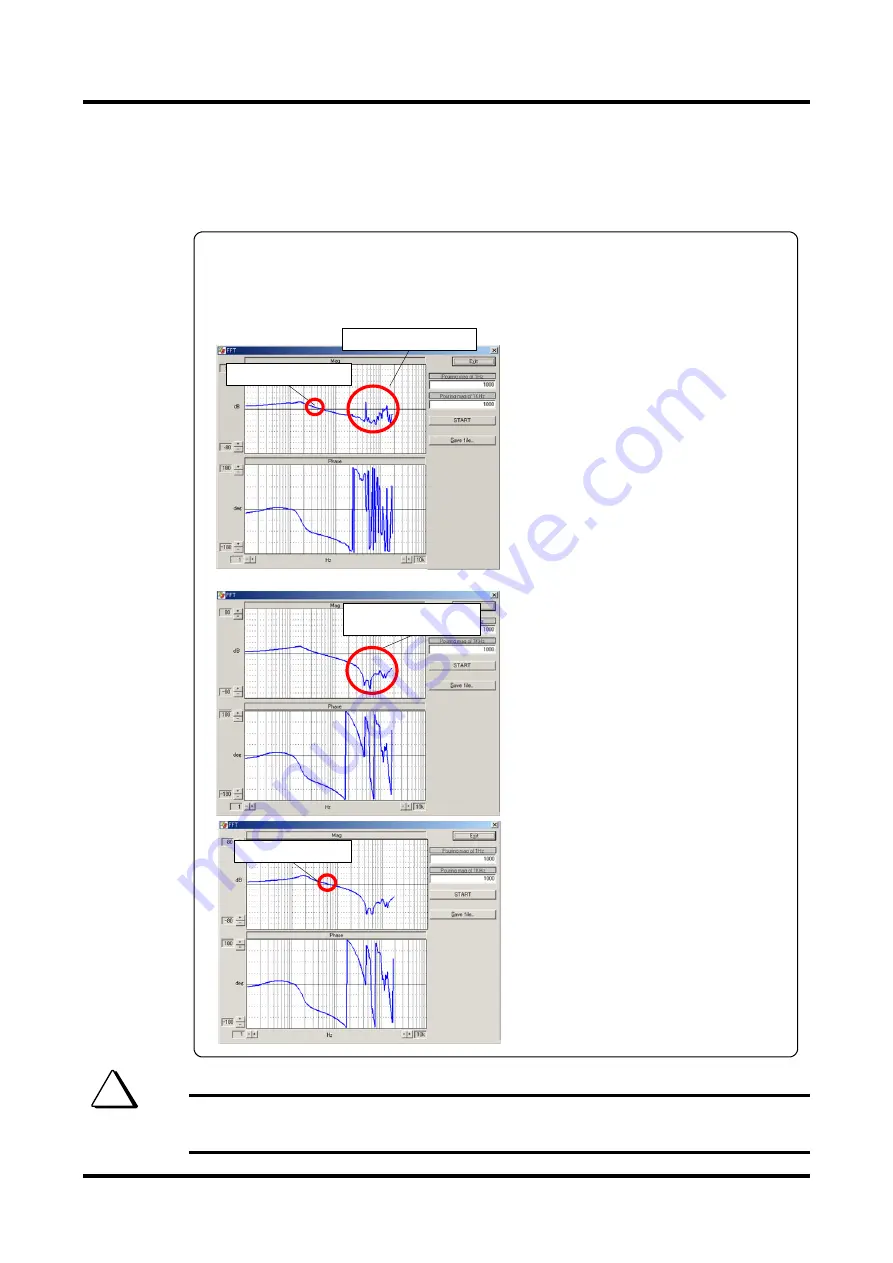

7.4.3 Usage Example of the FFT Function

Estimation of Resonance Frequency

The servo stiffness can be improved by estimating the resonance frequency and setting the

optimum filter.

The gain at the resonance point

is attenuated by the notch filter

Velocity bandwidth: 50 Hz

Mechanical resonance point

<Characteristics before tuning>

Velocity bandwidth: 50 Hz

Filter: None

Motor condition: The motor oscillates with

high frequency noise when it is operated.

The oscillation noise is not stopped

unless the velocity bandwidth is lowered

to 20 to 30 Hz.

<Characteristics after filter setting>

Velocity bandwidth: 50 Hz

Filter:

Notch filter 1: 450 Hz

Notch filter 2: 1200 Hz

Motor condition: The motor does not

oscillate and operates steadily.

<Characteristics after tuning>

Velocity bandwidth: 80 Hz

Filter:

Notch filter 1: 450 Hz

Notch filter 2: 1200 Hz

Motor condition: The motor does not

oscillate and operates steadily.

The settling time was reduced to

approximately half of that before

adjustment.

Velocity bandwidth: 80 Hz

<Measurement example>

Application: Index table of semiconductor chip parts

Problem: Since the index table is thin, it resonates and the servo stiffness does not

increase.

Note that inserting filters cause a phase shift in the closed loop. After adjusting the filters,

operate the motor and confirm that the velocity waveform does not vibrate using the

oscilloscope function.

TIP