Part 5: Review on Replacement of MR-J2S-30 kW or Higher Capacity Models with MR-J4-DU_

5 - 11

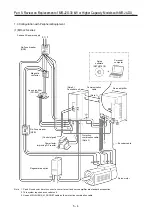

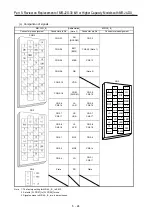

(1) General-purpose interface 200 V class

MR-J2S-_KA MR-J4-DU_A

3-phase

200 to

230 V AC

50/60 Hz

MR-A-TM

connector

termination

(Option)

MR-J2HBUS

M cable

Converter unit

Fan

Servo amplifier

Encoder cable

Servo motor

24 V DC

power

supply

thermal relay

(Note1)

Regenerative

brake option

(Note1)

Regenerative

brake option

(Note1)

Regenerative

brake option

(Note2)

Fan

Fan

Fan

Servo

relay

Motor thermal

Operation-ready

brake

Dynamic

Converter

Servo motor

Encoder

CN1

Power factor improving

DC reactor (Option)

MC

L

1

L

2

L

3

L

11

L

21

NFB

13 COM

12

8

VDD

3

ALM

SE

5

SG

RA3

P

N

P

N

N

P

N

CN5

CN5A

CN2

RA2

OSH1

BW

BV

BU

M

P

C

P

1

P

2

ON

MC

MC

SK

RA1

RA3

RA2 EMG OFF

VDD

COM

ALM

RA1

OHS2

P

V

U

W

CN5B

CN1B

L

11

L

21

V

U

W

G4

G3

P

C

G4

G3

C

P

S

R

G4

G3

P

C

S

R

S

R

NFB

MR-HCN2

3

13

18

3-phase

200 to 220 V AC/50 Hz

200 to 230 V AC/60 Hz

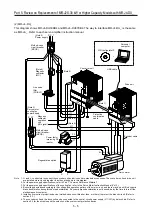

When magnetic contactor drive output is enabled (factory setting)

RA3

RA1

RA2

Converter unit

malfunction

Optional

thermal

Operation ready

OFF/ON

Drive unit

malfunction

Emergency stop

switch

MC

SK

MC

(Note 5)

MCCB

RA2

(Note 1)

Regenerative

option

Cooling fan

L+

L-

MR-J3CDL05M

cable

Converter unit

Drive unit

L1

L2

L3

L11

L21

3-phase

200 V AC to

240 V AC

1

MC1

2

MC2

CN40

CN40A

CN2

External

dynamic brake

(optional)

BV

M

Encoder

V

U

W

V

U

W

Servo motor

(Note 4)

Power

supply

TE2-2

L+

L-

TE2-1

C

P1

P2

Power factor improving

DC reactor (optional)

(Note 2)

L11

L21

G4

G3

P

C

G4

G3

P

C

S1

R1

G4

G3

P

C

S1

R1

S1

R1

CNP1

CN1

1

DICOM

5

DOCOM

6

DICOM

2

ALM

7

EM1

9

DOCOM

CN1

EM2

15

21

DOCOM

46

ALM

48

SON

42

DICOM

(Note 8) Encoder cable

24 V DC

24 V DC

MCCB

BW

BU

Cooling fan

(Note 6)

Main circuit power supply

(Note 7, 14)

RA3

24 V DC

(Note 11)

Short-circuit connector

(packed with the drive unit)

CN8

(Note 12)

(Note 9)

(Note 13)

(Note 10, 15)

RA1

24 V DC

(Note 12)

(Note 10, 15)

(Note 1)

Regenerative

option

Cooling fan

(Note 1)

Regenerative

option

Cooling fan

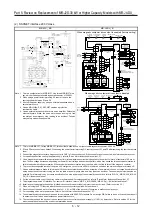

Note 1. This is a configuration for MR-RB137. Use three MR-RB137s in a

set, which provides permissible regenerative power of 3900 W.

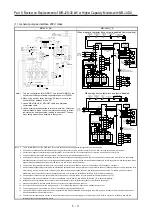

When magnetic contactor drive output is disabled

MC

(Note 5)

RA2

L+

L-

MR-J3CDL05M

cable

Drive unit

L1

L2

L3

L11

L21

MCCB

CN40A

(Note 12)

CN2

External

dynamic brake

(

optional

)

M

V

U

W

V

U

W

Servo motor

TE2-2

L+

L-

TE2-1

C

P1

P2

Power factor improving

DC reactor (

optional

)

(Note 2)

L11

L21

G4

G3

P

C

G4

G3

P

C

S1

R1

G4

G3

P

C

S1

R1

S1

R1

CN1

1

DICOM

5

DOCOM

6

DICOM

2

ALM

7

EM1

9

DOCOM

CN1

15

21

46

48

42

(Note 8) Encoder cable

24 V DC

BW

BV

BU

Encoder

(Note 4)

Power

supply

MCCB

Cooling fan

(Note 7, 14)

RA3

RA1

RA2

MC

MC

SK

CN40

1

MC1

2

MC2

CNP1

RA3

24 V DC

(Note 10, 15)

(Note 11)

Short-circuit connector

(packed with the drive unit)

CN8

(Note 9)

(Note 13)

(Note 3)

(Note 12)

(Note 10, 15)

Optional

thermal

Operation ready

Drive unit

malfunction

Emergency stop

switch

(Note 1)

Regenerative

option

3-phase

200 V AC to

240 V AC

Cooling fan

(Note 1)

Regenerative

option

Cooling fan

(Note 1)

Regenerative

option

Cooling fan

ON

OFF

converter unit

Converter unit

malfunction

EM2

ALM

DICOM

DOCOM

SON

24 V DC

(Note 5)

Main circuit power supply

RA1

24 V DC

2. When using a power factor improving DC reactor, remove the

short-circuit bar between P1 and P2.

3. Use an MR-J2HBUS_M_ SSCNET cable as a protection

coordination cable.

4. Use an external dynamic brake to this servo amplifier. Without an

external dynamic brake, the servo motor keeps running in a free

run state at an emergency stop, leading to an accident. Take as

many safety measures as possible in the system.

Note 1. This is for MR-RB137. For the MR-RB137, three units are used as one set (permissible regenerative power: 3900 W).

2. P1 and P2 are connected by default. When using the power factor improving DC reactor, connect P1 and P2 after removing the short bar across them.

3. Connect the magnetic contactor wiring connector to CNP1 of the converter unit. If the connector is not connected, an electric shock may occur.

4. For specifications of the cooling fan power supply, refer to "Servo Motor Instruction Manual (Vol. 3)".

5. Use a magnetic contactor with an operation delay time (interval between current being applied to the coil until closure of contacts) of 80 ms or less. The bus voltage

decreases depending on the main circuit voltage and operation pattern, which may cause the forced stop deceleration to shift to the dynamic brake deceleration. When

dynamic brake deceleration is not required, slow the time to turn off the magnetic contactor.

6. To prevent an unexpected restart of the drive unit, configure a circuit to turn off EM2 in the drive unit when the main circuit power is turned off.

7. Use an external dynamic brake to this drive unit. Without an external dynamic brake, activation of an alarm which does not cause deceleration to a stop keeps the servo

motor running in a free run state at an emergency stop, and may lead to an accident. Take as many safety measures as possible. For alarms which do not cause

deceleration to a stop and wiring of the external dynamic brake, refer to "MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

8. For the encoder cable, use of the option cable is recommended. For selecting cables, refer to "Servo Motor Instruction Manual (Vol. 3)".

9. This diagram shows sink I/O interface. For source I/O interface, refer to "MR-CV_/MR-CR55K_/MR-J4-DU_(-RJ) Instruction Manual".

10. Install an overcurrent protection device (molded-case circuit breaker or fuse) to protect the branch circuit. (Refer to section 5.3.)

11. When not using the STO function, attach the short-circuit connector supplied with the drive unit.

12. Do not connect the servo motor of a wrong axis to U, V, W, or CN2 of the drive unit. Otherwise, a malfunction may occur.

13. For connecting servo motor power wires, refer to "Servo Motor Instruction Manual (Vol. 3)".

14. The external dynamic brake cannot be used for compliance with SEMI-F47 standard. Do not assign DB. Failure to do so will cause the drive unit to become servo-off

when an instantaneous power failure occurs.

。

15. The converter unit and the drive unit can be connected to the control circuit power supply (L11/L21) by daisy chain. Refer to section 5.2 for the wire size and the

selection of the overcurrent protection device.

Содержание MELSERVO-J2-Super Series

Страница 18: ...Part 1 Summary of MR J2S MR J2M Replacement 1 1 Part 1 Summary of MR J2S MR J2M Replacement ...

Страница 31: ...Part 1 Summary of MR J2S MR J2M Replacement 1 14 MEMO ...

Страница 109: ...Part 3 Review on Replacement of MR J2S _B_ with MR J4 _B_ 3 32 MEMO ...

Страница 161: ...Part 4 Review on Replacement of MR J2S _CP_ CL_ with MR J4 _A_ RJ 4 52 MEMO ...

Страница 219: ...Part 5 Review on Replacement of MR J2S 30 kW or Higher Capacity Models with MR J4 DU_ 5 58 MEMO ...

Страница 220: ...Part 6 Review on Replacement of MR J2M with MR J4 6 1 Part 6 Review on Replacement of MR J2M with MR J4 ...

Страница 239: ...Part 6 Review on Replacement of MR J2M with MR J4 6 20 MEMO ...

Страница 240: ...Part 7 Common Reference Material 7 1 Part 7 Common Reference Material ...

Страница 284: ...Part 7 Common Reference Material 7 45 Click Update Project ...

Страница 342: ...Part 8 Review on Replacement of Motor 8 1 Part 8 Review on Replacement of Motor ...

Страница 409: ...Part 8 Review on Replacement of Motor 8 68 MEMO ...

Страница 461: ...Part 9 Review on Replacement of Optional Peripheral Equipment 9 52 MEMO ...

Страница 462: ...Part 10 Startup Procedure Manual 10 1 Part 10 Startup Procedure Manual ...

Страница 464: ... Appendix 1 Summary of MR J4_B_ RJ020 MR J4 T20 Appendix 1 1 Appendix 1 Summary of MR J4_B_ RJ020 MR J4 T20 ...