båÖäáëÜ

59 38 399 D3352

D3352.076.01.13.02

07.2008

6 – 29

Tab 6

6.8 Replacing/adjusting the MS light localizer laser module (PAN)

6.8

Adjusting the MS light localizer (PAN)

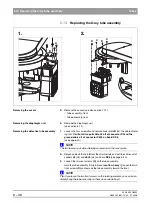

z

Insert

a bite block in the support piece.

z

Switch the unit

ON

.

z

Switch the light localizers

ON

and align the laser module (MS) so that the

MS light beam

(C)

strikes the center of the bite block or support piece.

z

Tighten screws

A

securely.

NOTE

i

Be careful not to turn the laser module any more when tightening the

screws.

z

Check the light localizer again and perform a correction if necessary.

Attaching the covers

z

Set the front slide cover down on the top support cover.

z

Plug the cable of the FH laser module back into connector

X807

on board

DX1

.

z

Reattach the top arm and front slide covers.

ATTENTION: What to do after replacement?

– No further action is required.

29

C

Summary of Contents for ORTHOPHOS XG 3 DS

Page 4: ......

Page 9: ...ORTHOPHOS XG 1General information...

Page 12: ...59 38 399 D3352 1 4 D3352 076 01 13 02 07 2008 Tab1...

Page 59: ...ORTHOPHOS XG 2 Messages...

Page 124: ...59 38 399 D3352 2 66 D3352 076 01 13 02 07 2008 2 6 List of available service routines Tab 2...

Page 125: ...ORTHOPHOS XG 3 Troubleshooting...

Page 153: ...ORTHOPHOS XG 4 Adjustment...

Page 269: ...ORTHOPHOS XG 5 Service routines...

Page 433: ...ORTHOPHOS XG 6 Repair...

Page 436: ...59 38 399 D3352 6 4 D3352 076 01 13 02 07 2008 Tab6...

Page 530: ...59 38 399 D3352 6 98 D3352 076 01 13 02 07 2008 6 21 Replacing cables Tabs 6...

Page 531: ...ORTHOPHOS XG 7 Maintenance...

Page 577: ...b 59 38 399 D3352 D3352 076 01 13 02 07 2008...