257

Control Units

Section 7-2

7-2

Control Units

7-2-1

Control Units for Position Control

Control Units for

Position Control

The command units are used as the basic control units for the position com-

mand values and speed command values that the PCU uses in position con-

trol axis operations, such as direct operation, origin searches, and jogging.

(The unit for speeds is command units/s.) These units are determined by the

electronic gear ratio in the Servo Parameters. The Servo Parameter settings

such as

Positioning Completion Range

and

Software Limit

and the present

position monitor unit input in the CPU Unit are also based on these command

units.

The

Electronic Gear Ratio G1/G2

parameters determine the ratio between the

command unit and travel distance (pulse unit) of the Servomotor.

Set the electronic gear ratio such that 0.01

≤

G1/G2

≤

100 when using R88D-

GN

@

G-series Servo Drives, R88D-WT

@

W-series Servo Drives, or SMART-

STEP Junior Servo Drives and such that 0.001

≤

G1/G2

≤

1000 when using

R88D-WN

@

-ML2 W-series Servo Drives.

In the Servo Drive, the control unit is the pulse unit determined by the Servo-

motor's encoder resolution. (The Servo Drive operates internally with a pulse

multiplier of four. Therefore, the Servomotor's encoder resolution multiplied by

four is the number of pulses in one rotation.) The electronic gear ratio is used

to convert the command value (i.e., command units) handled by the PCU into

the control unit (i.e., pulses) used in the Servo Drive (the G1/G2 unit is

pulses/command unit.) When the Servo Drive’s default setting (G1/G2 = 4/1)

is used, the command unit is the number of pulses equivalent to the Servomo-

tor's encoder resolution.

Servomotor with 2,048

(Pulses/Rotation) Encoder

When set to G1/G2 = 8192/1000, the command units for which the Servomo-

tor makes one rotation for a position command value of 1,000 can be

obtained.

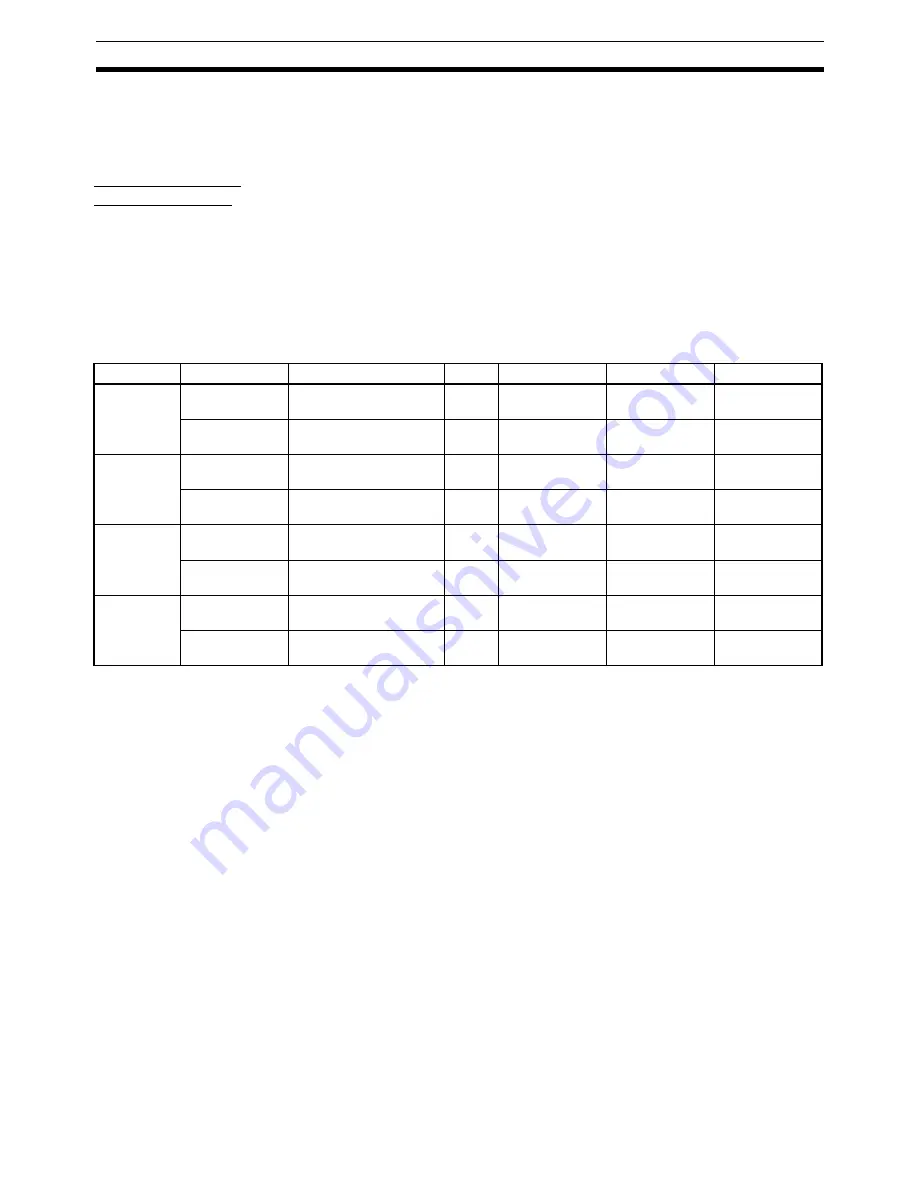

Model

Parameter No.

Parameter name

Unit

Setting range

Parameter size

Default setting

R88D-GN

@

-

ML2

Pn205

Electronic gear ratio 1

(numerator)

---

0 to 131072

4

1

Pn206

Electronic gear ratio 2

(denominator)

---

1 to 65535

4

1

R88D-WT

@

Pn202

Electronic gear ratio G1

(numerator)

---

1 to 65535

2

4

Pn203

Electronic gear ratio G2

(denominator)

---

1 to 65535

2

1

R88D-WN

@

-

ML2

Pn20E

Electronic gear ratio G1

(numerator)

---

1 to

1073741824

4

4

Pn210

Electronic gear ratio G2

(denominator)

---

1 to

1073741824

4

1

SMART-

STEP Junior

Pn20E

Electronic gear ratio G1

(numerator)

---

1 to

1073741824

4

1

Pn210

Electronic gear ratio G2

(denominator)

---

1 to

1073741824

4

1

Summary of Contents for CJ1W-MA - REV 10-2008

Page 3: ...iv ...

Page 5: ...vi ...

Page 21: ...xxii ...

Page 57: ...30 Starting Operation Section 2 2 ...

Page 97: ...70 Wiring Section 3 4 ...

Page 247: ...220 Transferring Servo Parameters Section 5 3 ...

Page 281: ...254 Standard Settings for Servo Drives Using MECHATROLINK Section 6 4 ...

Page 343: ...316 Absolute Encoder Origin Section 8 6 ...

Page 375: ...348 Linear Interpolation Section 9 7 ...

Page 423: ...396 DEVIATION COUNTER RESET Section 10 10 ...

Page 631: ...604 Additional Functions for the CJ1W NCF71 MA Appendix F ...

Page 641: ...614 Index ...

Page 643: ...616 Revision History ...