MPH-02, MPB-02, MPD-02

Drive Control

6-57

DOK-INDRV*-MP*-02VRS**-FK01-EN-P

To determine the "critical proportional gain" proceed as follows:

1. Let the drive move with low velocity after switching drive enable on:

•

linear

motor

→

1000 … 2000 mm/min

•

rotary

motor

→

10 … 20 rpm

2. Increase value in parameter

S-0-0100, Velocity loop proportional

gain

until instable behavior (continuous oscillation) occurs.

3. Determine frequency of oscillation by oscilloscoping the actual

velocity (see also "Analog Outputs" or "Oscilloscope Feature"). When

frequency of oscillation is considerably higher than 500 Hz, increase

value in parameter

P-0-0004, Velocity loop smoothing time

constant

until oscillation diminishes. Then continue increasing the

value in parameter

S-0-0100, Velocity loop proportional gain

until

oscillation (instability) occurs again.

4. Reduce

parameter

S-0-0100, Velocity loop proportional gain

until

permanent oscillation decreases automatically.

The value thus determined is the so-called "critical velocity loop

proportional gain".

Note:

By using the filter cascade (P-0-1120, P-0-1121, P-0-1122,

P-0-1123) it is possible to activate a PT4-filter.

To determine the "critical integral action time" proceed as follows:

1. Set parameter

S-0-0100, Velocity loop proportional gain

=

0.5 * "critical proportional gain"

2. Reduce value in parameter

S-0-0101, Velocity loop integral action

time

, beginning with maximum value, until instable behavior

(continuous oscillation) occurs.

3. Increase value in parameter

S-0-0101, Velocity loop integral action

time

until continuous oscillation decreases automatically.

The value thus determined is the "critical integral action time". Usual

values are within the range from 5 to 20 ms!

From the determined critical values (see above) it is possible to derive a

controller setting with the following characteristics:

•

independent of changes at the axis because sufficient distance to

stability limit

•

properties can be reliably reproduced in series machines

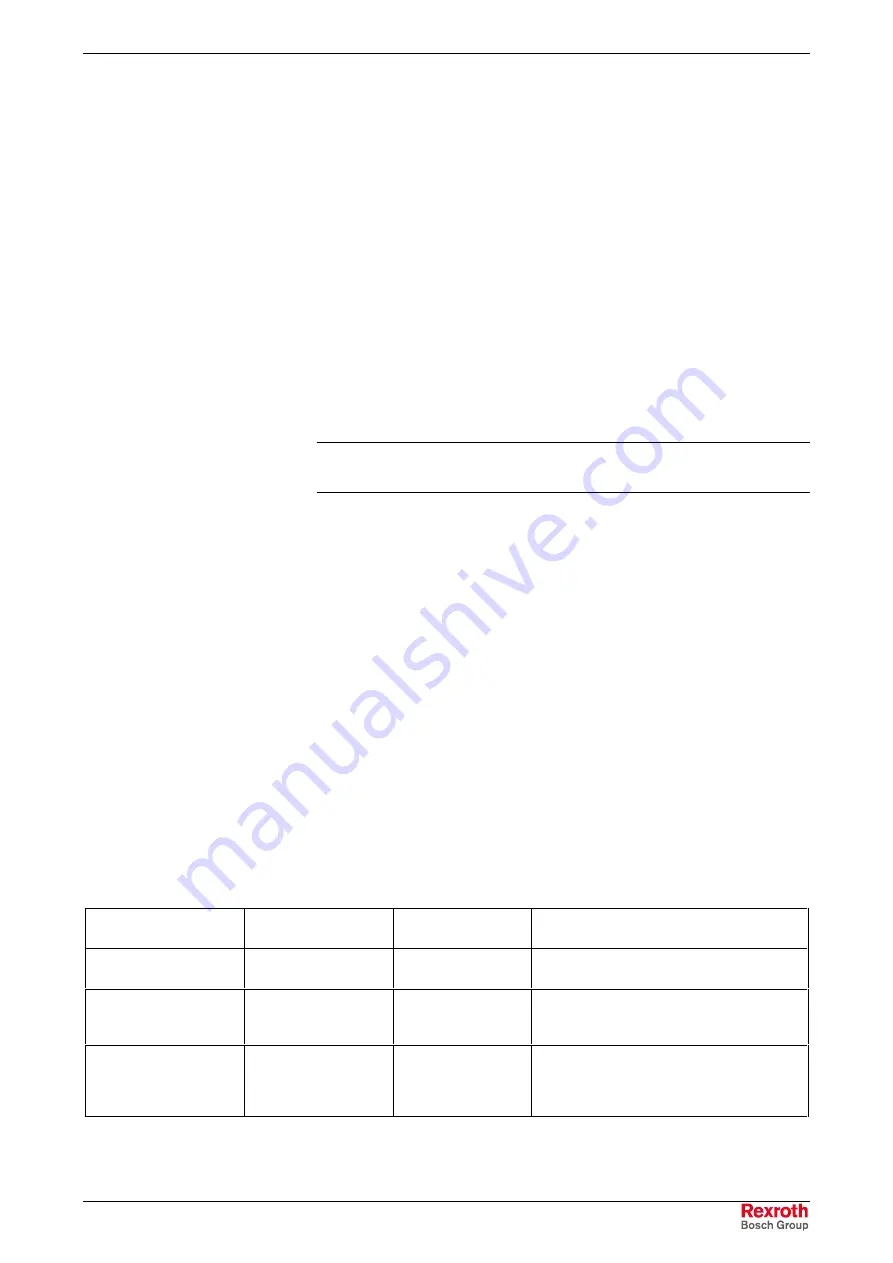

The following table contains some of the most common types of

application and the corresponding characteristics of the control loop

setting.

Application type

Speed controller

proportional gain

Speed controller

integral action time

Notes

feed axis at standard

machine tool

K

p

= 0.5 x K

pkrit

T

n

= 2 x T

nkrit

good load stiffness and good control

performance

feed axis at perforating

machine or nibbling

machine

K

p

= 0.8 x K

pkrit

T

n

= 0

high proportional gain; no I-component in

order to obtain short response times

feed drive at following-

on cutting devices

K

p

= 0.5 x K

pkrit

T

n

= 0

relatively non-dynamic controller setting

without I-component in order to keep the

material to be cut from getting distorted with

the cutting device

Fig. 6-40: Characteristics of controller setting

Determining the Critical

Proportional Gain

Determining the Critical Integral

Action Time

Characteristics of Controller

Setting

Courtesy

of

CMA/Flodyne/Hydradyne

▪

Motion

Control

▪

Hydraulic

▪

Pneumatic

▪

Electrical

▪

Mechanical

▪

(800)

426-5480

▪

www.cmafh.com