14.1 Fundamental settings

14-27

Spindle drive

If a External encoder is to be used at a Spindle drive, the encoder at the Spindle motor must

be a serial encoder. You cannot use pulse encoders both for motor encoder and for External

encoder at the same time.

• MD6530 (Cn530) ENCODER_SPECIFICATION_1 (For each axis)

Meaning:

External encoder specification

Setting value: Bit 1, 0

0, 0 --- No encoder used.

0, 1 --- External encoder used.

1, 0 --- Motor encoder used.

Bit 2

0 --- CCW rotation to be treated as forward rotation.

(1 --- CW rotation to be treated as forward rotation.)

Note: To set up reverse rotation connection, use CNC parameter.

Bit 6

0 --- Incremental encoder

1 --- Absolute encoder

Bit 7

0 --- Pulse encoder

1 --- Serial encoder

• MD6534 (Cn534) NUMBER_OF_ENCODER_PULSE_1 (For each axis)

Meaning:

The number of motor encoder pulses (4-multiplication value)

Setting value: 11 --- 2048 Pulse encoder

12 --- 4096 Pulse encoder

13 --- 8192 Pulse encoder

19 --- 19-bit Serial encoder

Note: If this parameter is set to a number ranging from 8 to 32, the parame-

ter represents a value of n in "2 to the n-th power" pulse type

encoder. If the parameter is set to "32" or larger number, the parame-

ter represents the number of 4-multiplication pulses of a pulse

encoder.

• MD6915 (Cn87F) FULL_CLOSED_PG_PULSE_L_1 (For each axis)

Meaning:

The number of PG pulses used for position control / Single revolution of

motor (Lower word)

Setting value: [Pulse]

• MD6916 (Cn880) FULL_CLOSED_PG_PULSE_H_1 (For each axis)

Meaning:

The number of PG pulses used for position control / Single revolution of

motor (Upper word)

Setting value: [Pulse]

Note: If a External encoder is used, set MD6915 and MD6916 to the num-

ber of pulses of the External encoder.

Assign a 4-multiplication number to MD6915 and MD6916.

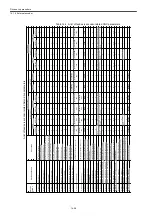

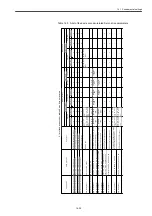

The next 2 pages show lists of machine data and parameters to be set in accordance with

specifications of feed axis-related motor encoder and External encoder.

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...