SIMATIC manager and hardware configuration

9.2.3 Opening the hardware configuration

9-6

9.2.3 Opening the hardware configuration

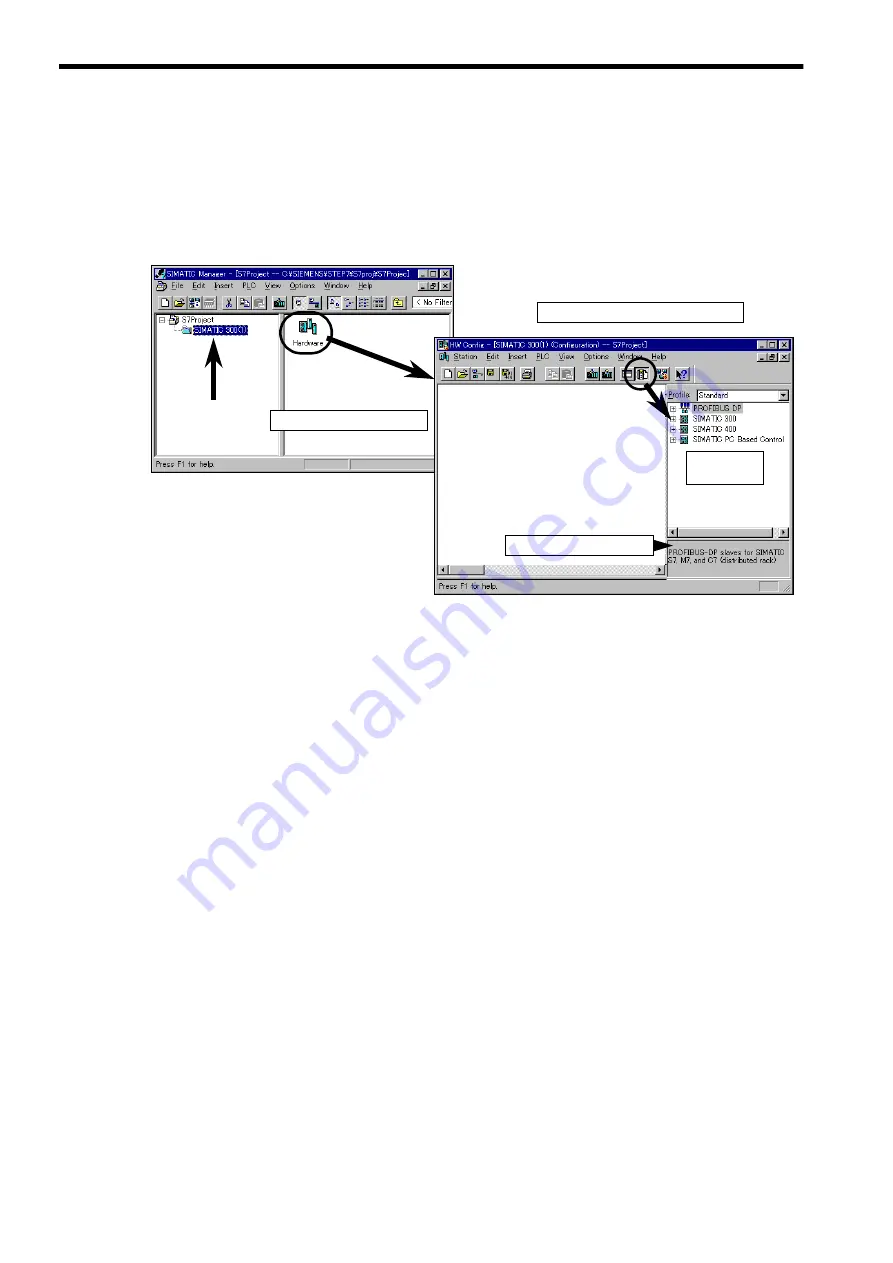

For hardware environment settings, such as PLC module configuration, CPU environment

setting, and module address setting, you will use the hardware configuration screen to open

the hardware configuration.

1. Click on a station (SIMATIC 300 Station (1) in this example) in the SIMATIC manager

screen.

2. Double-click on the Hardware icon in the right frame.

The hardware configuration function will start up.

If the selected station has its hardware already configured, that hardware configuration

is displayed. If not, a blank window results (see the figure above).

3. Click on the catalog icon of the hardware configuration screen’s tool bar.

A hardware catalog is displayed listing the modules and other products for the

SIMATIC300, SIMATIC400, and PROFIBUS-DP categories.

You can create a new hardware configuration in the hardware configuration window using

these products. For example, click on the plus sign (+) before the SIMATIC300 category in

the hardware catalog, and the following product groups will be displayed:

②

②

②

②

①

①

①

①

ハードウェアコンフィグレーション画面

Hardware configuration screen

ハードウェアをダブルクリック

Double-click on Hardware

ハードウェア

カタログ

Hardware

catalog

③

③

③

③

Order number and other

information

•

CP-300

Communication processor

•

CPU-300

CPU

•

FM-300

Function module

•

IM-300

Interface module

•

PS-300

Power supply module

•

Rack-300

Rack

•

SM-300

Signal module (I/O)

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...