10.1 Screen operation

10-3

10.1.2 Basic operation

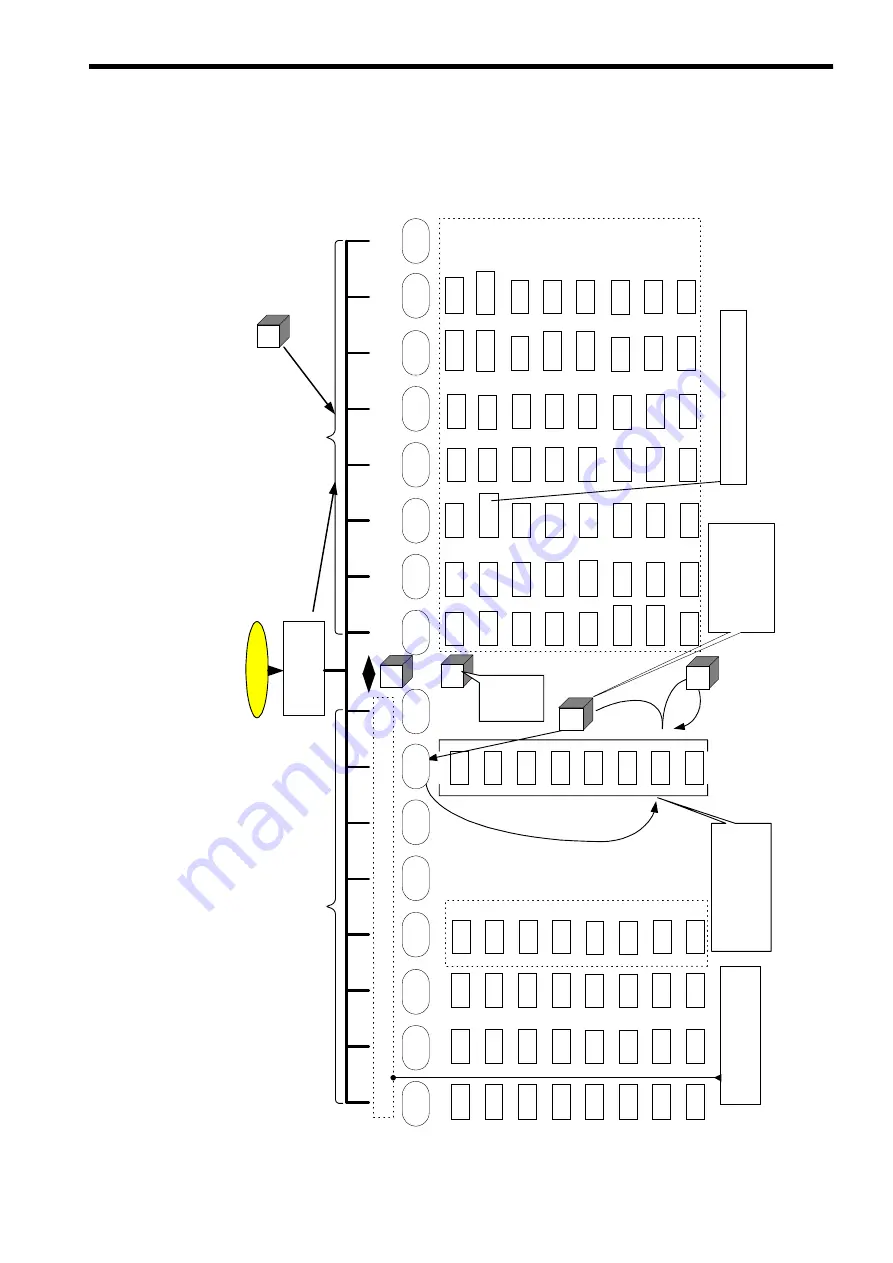

The following screen tree shows the transition of screen states.

Power ON

HS5

HS6

HS7

HS8

HS1

HS2

HS3

HS4

Setting

HS4

Initial screen

(Wallpaper)

When power is supplied, ShopMill

screen displays.

NC

* 2

PC CARD

M

You can return to the ShopMill

screen from any screen.

II

V

V

V

Service *1

HS1

Diagnosis

HS2

Start-up

HS3

Data

selection

Interfac

e

Alarm

Message

Alarm

log

PLC

status

Service

display

Remote

diagnosi

s

Machine

data

User

display

NC

Drive

servo

MMC

PLC

Tool

indication

setting

Input

Output

File

management

Manual

operation

Automatic

operation

Program

management

Program

Edit

User

message

Tool/Work

coordinate

system

COMMON

Simulation

Program

modificatio

n

STEP7

HS5

HS6

HS7

HS8

Setting

data

User

data

*1 If the exclusive customer screen

is added, the alignment between

HS1 and HS8 may be changed.

T,S,M...

...

Zero offset

origin

setting

Work origin

offset

Measur

ing tool

MDA

Positioning

Face

milling

Setting

Soft

switch

Program

control

Block

searching

Program

modificatio

n

Tool list

Tool

abrasion

List of

Compensati

on value

Magazine

Origin

offset

R

parameter

Position

batch

Running

hour

*2 If the PC card driver is connected, this F

key is displayed.

By pressing this key, only

the Function key display is

changed from HS1

(Service) until HS8

(Auxiliary) but the screen

is not changed.

When the Process key is

pressed down, there displays

each screen sequently and

subsequently the Function key

display is changed to

correspond each screen.

ShopMill

Standard

The level of

each screen

is changed

from the

lower to the

upper.

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...