14-

110

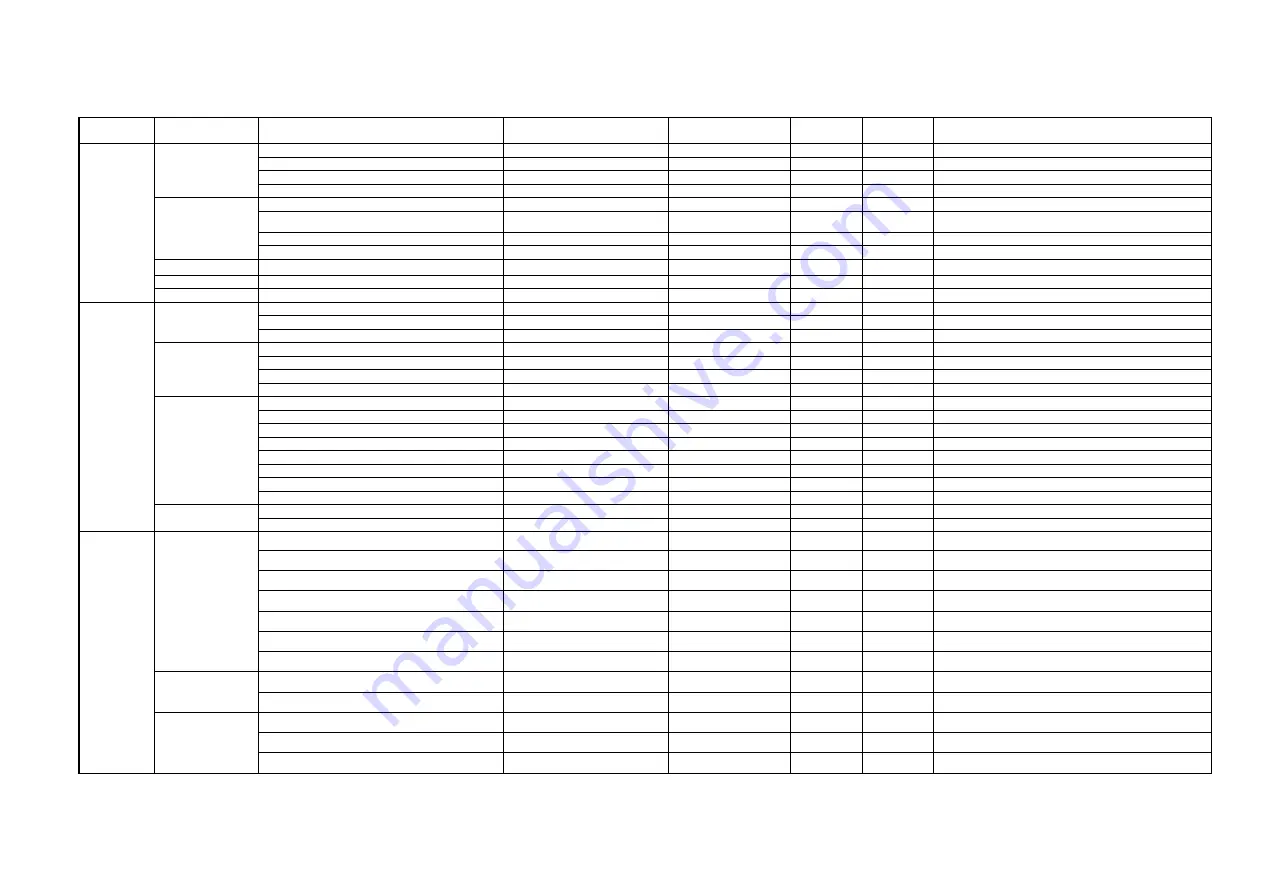

14.5.3 Spindle relevant parameter and Servo drive relevant parameter

Main topic

Topic

Subtopic

Name of Parameter

No. of Parameter

Typical Setting

Value

UNIT

General setting and others

Standard setting

Motor encoder

Encoder specification

ENCODER_SPECIFICATION_0

MD6529(Cn529)

-

-

Number of motor encoder pulse

NUMBER_OF_ENCODER_PULSE_0

MD6533(Cn533)

-

bit

11:2048/12:4096/13:8192/19:19bit serial

Number of PG pulse for position control/rotation of motor (lower word)

FULL_CLOSED_PG_PULSE_L_1

MD6915(Cn87F)

-

pulse

The number of pulse for motor encoder (multiplication-by-four value) is set.

Number of PG pulse for position control/rotation of motor (upper word)

FULL_CLOSED_PG_PULSE_L_1

MD6916(Cn880)

-

pulse

Separately mounted

encoder

Separately mounted encoder specification

ENCODER_SPECIFICATION_1

MD6530(Cn530)

-

-

Number of separately mounted encoder pulse

NUMBER_OF_ENCODER_PULSE_1

MD6534(Cn534)

-

-

The number of pulse (multiplication-by-four value) for 11:2048/12:4096/13:8192/19:19bit

serial/32 or higher

Number of PG pulse for position control/rotation of motor (lower word)

FULL_CLOSED_PG_PULSE_L_1

MD6915(Cn87F)

-

pulse

The number of pulse for separately mounted encoder (multiplication-by-four value) is set.

Number of PG pulse for position control/rotation of motor (upper word)

FULL_CLOSED_PG_PULSE_L_1

MD6916(Cn880)

-

pulse

Motor maximum speed

Rated speed

RATED_SPEED_SETTING

MD6500(Cn500)

-

min

-1

Mask setting

Alarm mask

ALARM_MASK

MD7081(Cn8E6)

-

-

Parameter initialization

Parameter initialization

RESERVED_FOR_USER_OF

MD6988(Cn8C8)

-

-

0: Initial value 1: Initialization

Servo drive

control

Position control

Multi-function selection SSC

MULTI_FUNCTION_SEL_SSC

MD6522(Cn522)

1

-

0: Soft start with SSC disabled 1: Servo mode with SSC enabled

Setting method for position loop gain

GAIN_SWITCH

MD6837(Cn831)

-

-

Excessive deviation range (over flow level)

OVERFLOW_LEVEL

MD6965(Cn8B1)

-

pulse

Speed control

Speed control proportion gain (H gear)

ASR_P_GAIN_H_1

MD6060(Cn060)

-

0.1%/Hz

Speed control integral time (H gear)

ASR_I_TIME_H_1

MD6061(Cn061)

-

0.1ms

Speed control proportion gain (M, L gear)

ASR_P_GAIN_M_L_1

MD6062(Cn062)

-

0.1%/Hz

Speed control integral time (M, L gear)

ASR_I_TIME_M_L_1

MD6063(Cn063)

-

0.1ms

Servo drive mode

Speed control proportion gain (servo mode H gear)

ASR_P_GAIN_H_2

MD6064(Cn064)

-

0.1%/Hz

Speed control integral time (servo mode H gear)

ASR_I_TIME_H_2

MD6065(Cn065)

-

0.1ms

Speed control proportion gain (servo mode M, L gear)

ASR_P_GAIN_M_L_2

MD6066(Cn066)

-

0.1%/Hz

Speed control integral time (servo mode M, L gear)

ASR_I_TIME_M_L_2

MD6067(Cn067)

-

0.1ms

Servo mode magnetic flux level (H gear)

SV_MODE_FLUX_LEVEL_H

MD6201(Cn201)

-

%

Servo mode base speed ratio (H gear)

SV_BASE_SPEED_RATIO_H

MD6202(Cn202)

-

0.01

Servo mode magnetic flux level (M, L gear)

SV_MODE_FLUX_LEVEL_M_L

MD6203(Cn203)

-

%

Servo mode base speed ratio (M, L gear)

SV_BASE_SPEED_RATIO_M_L

MD6204(Cn204)

-

0.01

Analog monitor

Monitor 1 output content

MONITOR_1_OUTPUT

MD6472(Cn472)

0

-

0: Motor speed

Monitor 1 output content

MONITOR_1_OUTPUT

MD6472(Cn472)

1

-

1: Torque reference

Motion control

Spindle sequence relevant

Zero speed detection level

ZERO-SPEED_DET_LEVEL

MD6030(CN030)

-

0.1min

-1

Zero speed detection range

ZERO-SPEED_DET_WIDTH

MD6031(Cn031)

-

0.1min

-1

Speed coincidence signal range

SPEED_AGREE_WIDTH

MD6400(Cn400)

-

%

Ratio for MD6500 (Cn500) is set.

Speed coincidence signal level

SPEED_DETECTION_LEVEL

MD6401(Cn401)

-

0.01%

Ratio for MD6500 (Cn500) is set.

Speed coincidence signal hysteresis

SPEED_DETECTION_WIDTH

MD6402(Cn402)

-

0.01%

Ratio for MD6500 (Cn500) is set.

Torque detection signal level

TORQUE_DETECTION_LEVEL

MD6410(Cn410)

-

0.1%

Ratio for 30-minute rated torque is set.

Torque detection signal hysteresis

TORQUE_DETECTION_WIDTH

MD6411(Cn411)

-

0.1%

Ratio for 30-minute rated torque is set.

Emergency stop

Emergency stop wait time

EMERGENCY_STOP_WAIT_TIME

MD6511(Cn511)

-

ms

Delay between servo cutoff and connector cutoff

TACTOR_OFF_DELAY_TIME

MD6819(Cn819)

-

ms

Torque control

Torque control level on motor side

TORQUE_LIMIT

MD6421(Cn421)

-

%

Torque control level on regenerator side

REGENERATION_TORQUE_LIMIT

MD6422(Cn422)

-

%

Variable torque control selection

TORQU_LIMIT_SELECT

MD6423(Cn423)

-

-

0: Disabled 1: Enabled

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...