Drive set-up procedure

14.3.11 Collision detection

14-84

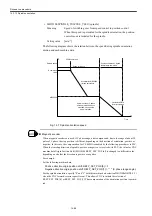

• MD3067 (Pn125) INERTIA_ADJ_DISTURB_OBSRVR (For each servo axis)

Meaning:

Disturbance observer inertia compensation

Setting value: [%]

• MD3368 (Pn412) DISTURB_TORQUE_LEVEL_1 (For each servo axis)

Meaning:

1st torque disturbance level

Disturbance level for feed except for positioning feed

Setting value: [%]

• MD3369 (Pn413) DISTURB_TORQUE_LEVEL_2 (For each servo axis)

Meaning:

2nd torque disturbance level

Disturbance level for positioning feed

Setting value: [%]

• MD3370 (Pn414) DISTURB_TORQUE_LEVEL_3 (For each servo axis)

Meaning:

3rd torque disturbance level

Disturbance level for forced entry

Setting value: [%]

• MD3371 (Pn415) DISTURB_TORQUE_LEVEL_4 (For each servo axis)

Meaning:

4th torque disturbance level

When Collision Detection is disabled

Setting value: [%]

Note: Be sure to set the parameter to "0".

• MD3372 (Pn416) COMPLIANCE_TORQUE (For each servo axis)

Meaning:

Compliance torque

Setting value: [%]

Relevant I/O

• DB3nDBX20. 2 (Torque limit 2) (For each servo axis)

Meaning:

Collision detection function enabled/disabled

By setting this signal to "1", the collision detection signal is enabled.

Setting value: 0---collision detection function disabled

1---collision detection function enabled

• DB3nDBX21. 2 (Drive parameter set selection d2) (For each servo axis)

Meaning:

Collision detection function forced input selection

Setting value: 0---forced input disturbance level disabled

1---forced input disturbance level enabled

• DB3nDBX93. 2 (Active drive parameter set d2) (per servo axis)

Meaning:

Collision detection function forced input selection state

Setting value: 0---forced input disturbance level not selected

1---forced input disturbance level selected

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...