System Configuration

1.1.1 General wiring drawing

1-2

1.1 System configuration

1.1.1 General wiring drawing

The following drawing shows how wiring is made between the components of the YS 840DI

system:

IO-USB Cable

CNC Unit PCU50

200 VAC

50/60Hz

Line filter

Reactor

Yaskawa Siemens 840DI

Ethernet

USB

VGA

Operation panel unit (color LCD)

OP10FS(Standard type)

OP10FT(Touch-panel type)

X121

PS/2 Keyboard

X111

X101

X1(24 VDC IN)

I/O module

power supply

Interface module(ET200M)

Digital I/O module

(6ES7321/322/323)

PROFIBUS-DP

Emergency stop/start

condition

Circuit breaker

SVM

PS/2 MOUSE

Machine panel I/O module

PS307

PROFIBUS-DP

Machine operation panel

input/output

24 VDC

24 VDC

200 VAC

Power module

PS module 10

Power backup

battery

UPS BATTERY

24 VDC

NC keyboard

Attached to OP10F

□

Display cable

Keyboard cable

Machine operation panel

OP032S

X20

MPI

X10

MPI

LPT1

PP Module

X2

X1

X111

X222

X333

PP Module

X2

X1

X111

X222

X333

Machine panel I/O module

PROFIBUS-DP

24 VDC

24 VDC

Machine input/

output

PROFIBUS-DP

PS307

24 VDC Machine input/

output

24

VDC

24

VDC

I/O module

I/O module

200 VAC

Power backup

module

UPS module 10

200 VAC

24 VDC

Emergency stop (input)

External power

supply

200 VAC

24 VDC

Emergency stop/start

condition

HNDLE PG

PC

CARD

Separately

mounted PG

PG(Pulse)

Separately

mounted PG

PG(Pulse)

1st motor

Spindle motor

Converter

CIMR-

MRXN

Inverter

CIMR-

MXN

Servo unit

(1-axis servo)

SGDK-

P N

CN5B

CN7B

P N

CN1

A1,A2

L1,L2,L3

P N

CN5B

CN7B

POWER

U,V,W,E

CN4

CN7A CN5A

P N

P N

CN7B CN5B

CN5A

CN9

Servo unit

(1-axis servo)

SGDK-

Terminating connector

POWER

CN2

CN8

CN7A CN5A

PG(Serial)

PG(Serial)

PG(Pulse or

separately mounted)

CN1

Terminating connector

PROFIBUS-DP

Bus bar

Separately

mounted PG

PG(Pulse)

CN7A CN5A

CN1

CN4

CN2

CN8

2nd motor

POWER

P N

P N

CN7B CN5B

200 VAC

200 VAC

Direct IN

Braking circuit for

the 2nd axes

Braking circuit for

the 3rd and 4th axes

Terminating

connector

CN2

PG(Serial)

Converter

CIMR-

MRXN

CN1

A1,A2

L1,L2,L3

P N

CN7B CN5B

CN5A

CN9

Terminating connector

PROFIBUS-DP

200 VAC

200 VAC

Servo unit

(2-axis servo)

SGDK-

CN12

CN18

PG(Serial)

PG(Serial)

CN7A CN5A

CN1

3rd motor

4th motor

POWER

POWER

CN28

CN22

P N

CN4

PG(Pulse)

Separately

mounted PG

CN1

CN24

CN14

Control power cable

Interface cable

Braking circuit for

the 1st axes

Separately

mounted PG

PG(Pulse)

Separately

mounted PG

PG(Pulse)

P N

CN7B CN5B

Servo unit

(2-axis servo)

SGDK-

Terminating connector

CN12

CN18

PG(Serial)

PG(Serial)

CN7A CN5A

CN1

5th motor

6th motor

POWER

POWER

CN28

CN22

P N

P N

CN7B CN5B

CN24

CN14

Direct IN

Braking circuit for the

5th and 6th axes

Bat

PROFIBUS-DP

USB

24 VDC

24 VDC

* Machine input/output

* From external power supply

* From external power supply

* From external power supply

24 VDC

PC card drive

NC ready (output)

COM1(25pin)

RS232C(D-sub9pin)

COM2(9pin)

RS232C(D-sub25pin)

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

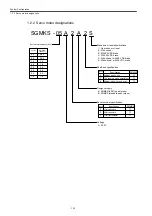

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...