Drive set-up procedure

14.3.14 Spindle winding changing

14-90

14.3.14 Spindle winding changing

Spindle winding changing is allowed via the spindle drive by the command form PLC

according to YS 840DI system specification.

Changing process

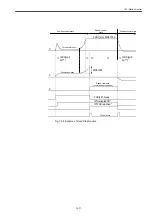

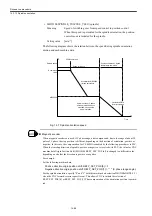

For example, the changing procedure with spindle speed detection signal (DBX94.5) is

shown below.

1. Set the spindle speed detection speed (MD6401 (Cn401)) for the winding changing

speed SCHW.

2. Set the spindle speed detection width (MD6402 (Cn402)) for the winding changing

speed hysteresis range

Δ

S.

MD6401, MD6402: Set the value in the units of 0.01 % of the rated revolution.

3. PLC detects ON/OFF for the spindle speed winding signal with DBX94.5.

4. PLC instructs the low-speed winding selection (DBX21.3 = 0, DBX21.4 = 0), and the

high-speed winding selection (DBX21.3 = 1, DBX21.4=0). (Switching command is per-

mitted with DBX21.5.)

5. PLC checks the winding selection status (DBX 93.3-4 agree with DBX 21.3.4) sent

from CNC and completes the process.

An example of time chart in case that switching speed is 1250min

-1

is shown below.

Fig. 14.9 Time chart for winding changing time chart

△

S

00

01

00

00

01

00

DBX94.5(SDET)

DBX21.3-4

DBX21.5

DBX93.3-4

500min

-1

2000min

-1

500min

-1

CNC program

Spindle command speed

Spindle real speed

0

0

500min

-1

2000min

-1

500min

-1

S

CHW

(1250min

-1

)

△

S

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...