14.3 Motion Control

14-85

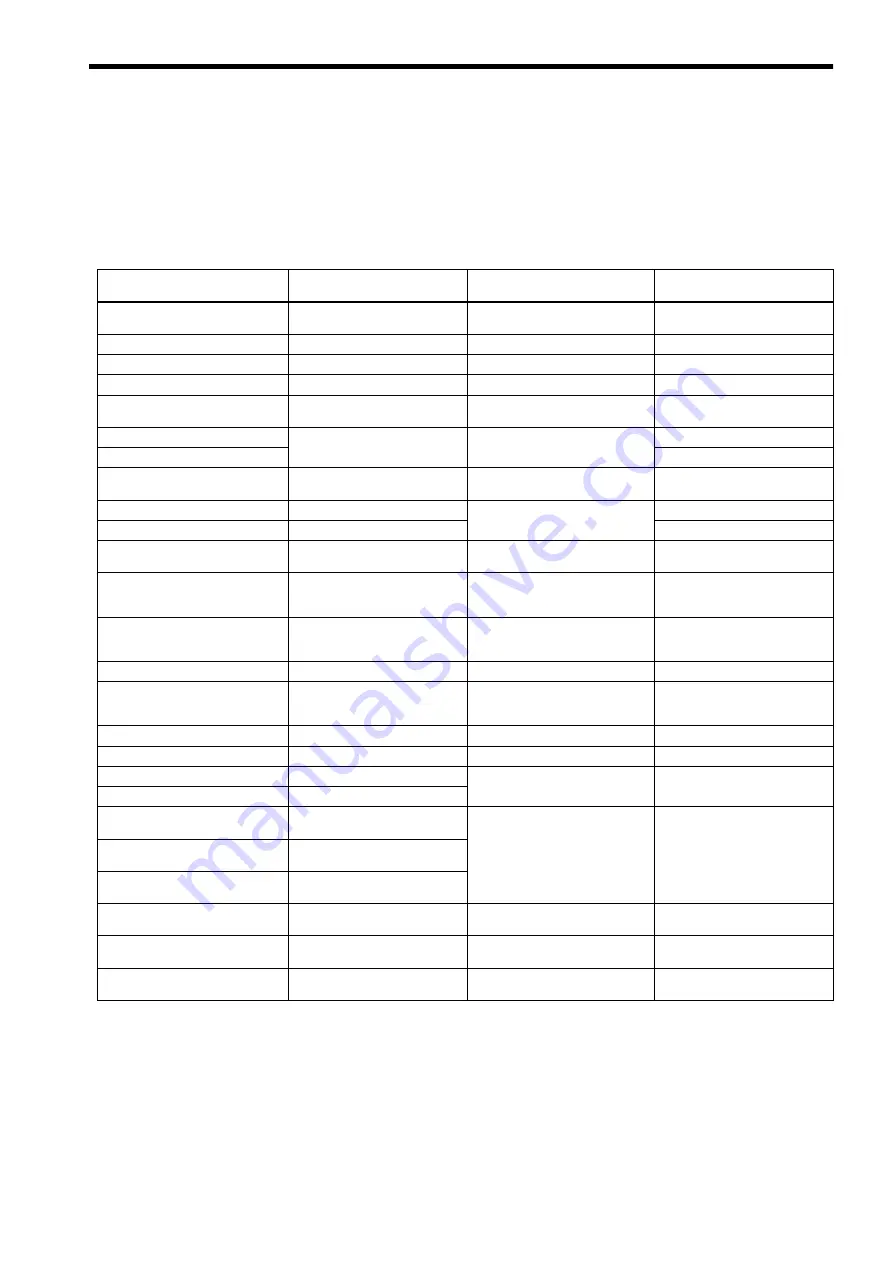

14.3.12 Spindle sequence I/O signals

Comparison of spindle sequence signals

The following table shows comparison of the spindle sequence signals with the conventional

spindle sequence signals.

Name of conventional signal

YS 840DI signal

Specification

(relation to the conventional)

Remarks

Emergency Stop (EMG)

None

Main supply ON is common to the servo

drive.

Operation is Ready (RDY)

DBB2.1 (Controller enable)

Same as RDY

Servo Drive ON and Forward (FOR)

DBX21.7 (Pulse enable)

Same as the servo drive

Servo Drive ON and Reverse (REV)

None

Reverse command is for CNC function

P/Pi Control Switching (PPi)

DBX21.6, DBX93.6

(controller integrator disable)

DBX21.6 is equal to PPi. DBX93.6 is

added to the completion check.

Also used for prevention of spindle

fluctuation. See section 14.3.13.

Orientation (ORT)

None

CNC function is enabled.

See 14.3.13.

Orientation Completion (ORE)

Soft Start (SSC)

None

Automatically enabled with spindle con-

trol system.

Torque Limit (TLH, TLL)

None

Limit value is specified from CNC.

Torque Limit Enabled (TLE)

None

Speed Agreement (SAGR)

DBX94.6 (nact=nset)

Equal to SAGR. ("1" for Speed agree-

ment)

See the parameters below.

Zero Speed detection (ZSPD)

DBX94.4(|nact|<nmin)

Equal to ZSPD. ("1" for the speed equal

or exceed setting value, "0" for the speed

less or equal to setting value)

See the parameters below.

Speed Detection (SDET)

DBX94.5(|nact|<nx)

Equal to SDET. ("0" for the speed equal

or exceed setting value, "1" for the speed

less or equal to setting value)

See the parameters below. Also see

14.3.14.

Load axis origin (ORG)

None

Torque Detection (TDET)

DBX94.3(Md<Mdx)

Equal to TDET. ("0" for the speed equal

or exceed setting value, "1" for the speed

less or equal to setting value)

See the parameters below.

Fault (FLT)

None

CNC

Malfunction Warning

None

Change Winding Request (CHW)

DBX21.3-5(Motor selection)

Different specification

See 14.3.14

Change Winding Completion (CHWE)

DBX93.3-4(Active motor)

Gear Changing (MGR,LGR)

DBX21.0-2,DBX93.0-2

(Drive parametr set selection)

Different specification

See 14.3.15

C Axis Changing Request (CAX)

DBX21.0-2

(Drive parameter set selection)

C Axis Changing Completion (CAXE)

DBX93.0-2

(Active drive parameter set)

-

DBX94.0

(Motor temperature prewarning)

Abnormal motor temperature alarm

(Normal; "1", Alarm; "0")

YS 840DI only

-

DBX94.1

(Heat sink temperature prewarning)

Abnormal heat sink temperature alarm

(Normal; 1, Alarm; 0)

YS 840DI only (also servo axis)

- DBX95.0

(UDC-link<alarm threshold)

Undervoltage alarm (Normal; "1"

Alarm; "0")

YS 840DI only (also servo axis)

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...