Drive set-up procedure

14.3.15 Spindle gear changing and Spindle integrated with C axis control

14-92

14.3.15 Spindle gear changing and Spindle integrated with C axis control

The spindle changing for the spindle gear changing or the spindle/C axis changing under the

spindle integrated C axis control is permitted via the spindle drive by the command from

PLC according to the spindle parameter changing specification of YS 840DI system specifi-

cation.

Parameter changing to H gear, M gear, L gear, or C axis is initiated by PLC when PLC veri-

fys the request for the parameter selection status number (DBX21.0 - 2) sent from PLC to

CNC and also the completion of changing the parameter selection status number (DBX93.0

- 2) from CNC to PLC. For the parameter changing, the parameter selection number in rela-

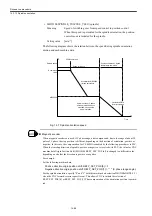

tion with each gear selection and C axis selection, and a skeleton time chart is shown below.

Note: If you do not use the gear changing or C axis control, select H gear.

Fig. 14.10 Spindle parameter selection time chart

DBX21. 0 to 2 (PLC -> CNC)

DBX93. 0 to 2 (CNC -> PLC)

Usage

0

C axis selection (CAX)

1

L gear selection (LGR)

2

M gear selection (MGR)

3

H gear selection

4 - 6

Reserved (currently H gear selection)

7

H gear selection (default)

Spindle parameter

selection

PLC -> CNC

DBX21.0-2

3

3

2

2

1

3

1

3

H gear

M gear

L gear

H gear

Parameter changing within spindle drive

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...