14.3 Motion Control

14-95

• MD21310 COUPLING_MODE_1

Meaning:

Spindle synchronicity mode

Setting value: 0---actual value coupling: Slave axis synchronizes with the master axis

position feedback value

1---setpoint coupling: The salve axis synchronizes with the master axis

position reference value.

2---speed coupling: Speed synchronization control

(normally not used since the position control is not executed in this

mode)

• MD21320 COUPLING_BLOCK_CHANGE_CTRL_1

Meaning:

Block changing mode during synchronicity

Setting value: 0---immediately change

1---change when ’Fine synchronism’ tolerance MD37210 is initiated

2---change when ’coarse synchronism’ tolerance MD37200 is initiated

• MD21330 COUPLING_RESET_MODE_1

Meaning:

Synchronicity setting when rest

• MD21340 COUPLING_IS_WRITE_PROT_1

Meaning:

Synchronicity conditions modifying setting

Setting value: 0---adjustable with CNC program

1---not adjustable with CNC program

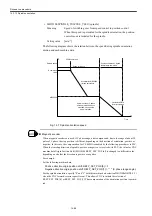

• MD37200 COUPLE_POS_TOL_COARSE

Meaning:

’Coarse synchronism’ tolerance range

Setting value: [mm] or [deg]

• MD37210 COUPLE_POS_TOL_FINE

Meaning:

’Fine synchronism’ tolerance range

Setting value: [mm] or [deg]

• SD42300 COUPLE_RATIO [0]

Meaning:

Numerator for synchronicity speed ratio

• MD42300 COUPLE_RATIO [1]

Meaning:

Denominator for synchronicity speed ratio

Setting value: Sets synchronicity speed ratio for spindle/following axis synchronizing

with spindle

Speed ratio = SD42300[0]/SD42300[1]

Settable with CNC program.

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...