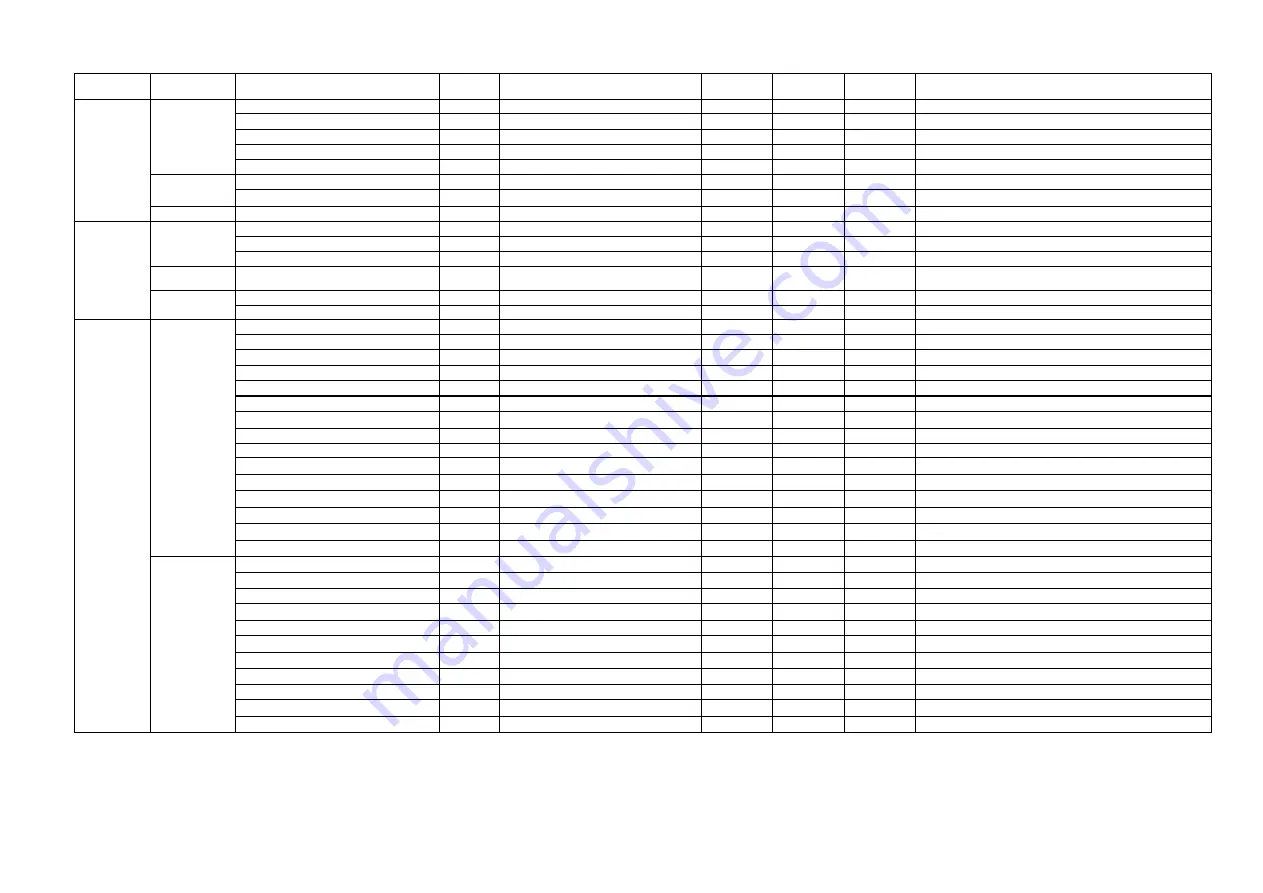

14-

104

Standard

setting

(Cont’d)

Separately

mounted

encoder

(Cont’d)

Separately mounted encoder enabled/disabled

Feed axis/Spindle

ENC_IS_DIRECT[1]

MD31040

-

-

0: Disabled 1: Enabled

Separately mounted encoder pulse multiplication

Feed axis/Spindle

ENC_PULSE_MULT[1]

MD31025

-

-

Separately mounted encoder rotation direction

Feed axis/Spindle

ENC_FEEDBACK_POL[1]

MD32110

-

-

0 or 1: Forward -1: Reverse

Separately mounted encoder function

Feed axis/Spindle

STIFFNESS_CONTROL_CONFIG

MD32642

1

-

0: Type 1 1: Type 2 Specify "0" when not using separately mounted encoders.

Multi-turn limit setting value

Feed axis/Spindle

ENC_ABS_TURNS_MODULO[1]

MD34220

1

rev

When linear scale is enabled, this setting is not required.

Motor maximum

speed

Percentage of motor maximum speed for speed reference

Feed axis/Spindle

RATED_OUTVAL[0]

MD32250

100

%

Motor maximum speed

Feed axis/Spindle

RATED_VELO[0]

MD32260

-

min

-1

Specify value for MD880.

Mask

Drive function mask

Feed axis/Spindle

DRIVE_FUNCTION_MASK[0]

MD13070

0

-

Servo control

Position control

Setting unit for position loop gain

Feed axis/Spindle

SCALING_FACTOR_USER_DEF[9]

MD10230

1.0

1/s

Common to whole axes

Position loop gain

Feed axis/Spindle

POSCTRL_GAIN[0]

MD32200

-

1/s

Unit depends on setting value with MD10230[9].

Maximum tolerance

Feed axis/Spindle

CONTOR_TOL

MD36400

-

mm,deg

Backlash

compensation

Backlash compensation

Feed axis/Spindle

BACKLASH[0]

MD32450

-

mm,deg

Each control

CNC feed mode to the drive

Feed

PROFIBUS_CTRL_CONFIG

MD37610

1

-

Used for prediction control, model following control, gain changing, and collision detection.

CNC feed mode to the drive

Spindle

PROFIBUS_CTRL_CONFIG

MD37610

0

-

Unavailable for Spindles.

Motion control

Feed rate

Feedback low pass filter (motor encoder)

Feed axis/Spindle

ENC_ACTVAL_SMOOTHTIME[0]

MD34990

-

sec

Mainly used when Spindle encoder resolution is not high enough.

Feedback low pass filter (separately mounted encoder)

Feed axis/Spindle

ENC_ACTVAL_SMOOTHTIME[1]

MD34990

-

sec

Mainly used when Spindle encoder resolution is not high enough.

Memory operation maximum speed

Feed

MAX_AX_VERO

MD32000

-

mm/min,deg/min

Maximum speed for G0, G1, etc.

RAPID speed in JOG mode

Feed

JOG_VELO_RAPID

MD32010

-

mm/min,deg/min

JOG speed

Feed

JOG_VELO

MD32020

-

mm/min,deg/min

Positioning command maximum speed

Feed

POS_AX_VELO

MD32060

-

mm/min,deg/min

POS command maximum speed

Speed limiting value

Feed

AX_VELO_LIMIT

MD36200

-

min

-1

The peed which triggers alarm.

Percentage of maximum speed reference

Feed

CTRLOUT_LIMIT

MD36210

110

%

Gear enabled/disabled

Spindle

GEAR_STEP_CHANGE_ENABLE

MD35010

1

Spindle maximum speed

Spindle

SPIND_VERO_LIMIT

MD35100

-

min

-1

The nth gear maximum speed

Spindle

GEAR_STEP_MAX_VERO[n]

MD35110

-

min

-1

The nth gear minimum speed

Spindle

GEAR_STEP_MIN_VERO[n]

MD35120

-

min

-1

The nth gear maximum speed limiting value

Spindle

GEAR_STEP_MAX_VERO_LIMIT[n]

MD35130

-

min

-1

The nth gear minimum speed limiting value

Spindle

GEAR_STEP_MIN_VERO_LIMIT[n]

MD35140

-

min

-1

Spindle position control mode maximum speed

Spindle

SPIND_POSCTRL_VERO

MD35300

-

min

-1

Acceleration/

deceleration

Acc./dec. jerk default setting

Feed

GCODE_RESET_VALUES[20]

MD20150[20]

2

-

1: BRISK 2: SOFT

Acc./dec. jerk

Feed

MAX_PATH_JERK

MD20600

-

mm/sec

3

,deg/sec

3 Generally set a larger value than MD32431.

Acceleration factor in curve section

Feed

CURV_EFFECT_ON_PATH_ACCEL

MD20602

0.75

-

Acceleration rate

Feed

MAX_AX_ACCEL

MD32300

-

mm/sec

2

,deg/sec

2 Common to G0 and G1.

Corner speed difference factor

Feed

MAX_ACCEL_OVL_FACTOR

MD32310

-

-

Acc./dec. jerk

Feed

MAX_AX_JERK

MD32431

-

mm/sec

3

,deg/sec

3 Common to G0 and G1.

Jerk limit between blocks

Feed

PATH_TRANS_JERK_LIM

MD32432

-

mm/sec

3

,deg/sec

3

Acceleration factor for G00

Feed

G00_ACCEL_FACTOR

MD32434

-

-

Acc./dec. jerk factor for G00

Feed

G00_JERK_FACTOR

MD32435

-

-

Acceleration under the nth gear speed contro

Spindle

GEAR_STEP_SPEEDCTRL_ACCEL[n]

MD35200

-

r/sec

2

Acceleration under the nth gear position control

Spindle

GEAR_STEP_POSCTRL_ACCEL[n]

MD35210

-

r/sec

2

Main topic

Topic

Subtopic

Axis

Name of Machine Data

No. of Machine

data

Typical Setting

Value

UNIT

General setting and others

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...