Maintenance 2. Regular Maintenance Inspection

RC180 Rev.17

117

2. Regular Maintenance Inspection

Performing regular maintenance inspection properly is essential for preventing trouble and

maintaining safety. This chapter describes the schedules for maintenance inspection and

procedures.

Be sure to perform the maintenance inspections in accordance with the schedules.

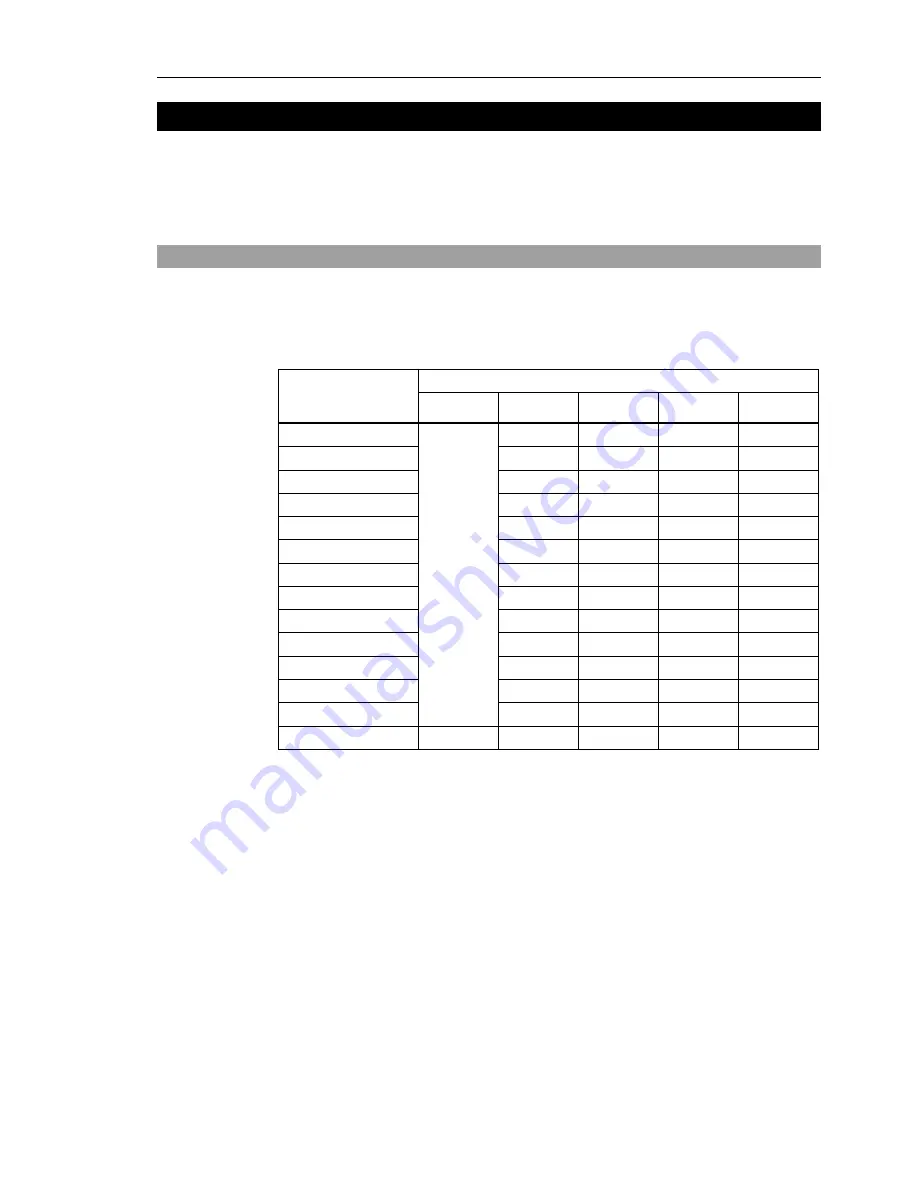

2.1 Schedule for Maintenance Inspection

Inspection points are divided into five stages: daily, monthly, quarterly, biannual, and

annual. Inspection points are added at every stage.

If the robot system is operated for 250 hours or more per month, inspection points must be

added every 250 hours, 750 hours, 1500 hours, and 3000 hours operation.

Inspection Point

Daily

inspection

Monthly

inspection

Quarterly

inspection

Biannual

inspection

Annual

inspection

1 month (250 h)

Ins

p

ec

t ev

er

y

d

ay

2 months (500 h)

3 months (750 h)

4 months (1000 h)

5 months (1250 h)

6 months (1500 h)

7 months (1750 h)

8 months (2000 h)

9 months (2250 h)

10 months (2500 h)

11 months (2750 h)

12 months (3000 h)

13 months (3250 h)

…

…

…

…

…

…

Summary of Contents for RC180

Page 1: ...Rev 17 EM164C3205F ROBOT CONTROLLER RC180 ...

Page 2: ...ROBOT CONTROLLER RC180 Rev 17 ...

Page 13: ...Safety This section contains information for safety of the Robot System ...

Page 14: ......

Page 20: ......

Page 124: ...Setup Operation 12 Option Units 112 RC180 Rev 17 ...

Page 125: ...Maintenance This section contains maintenance procedures for the Robot Controller ...

Page 126: ...114 ...