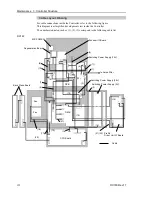

Maintenance 3. Controller Structure

RC180 Rev.17

123

RC180 Cable List

Cable

No.

Connection

Connector Pin

Quantity

Wire

Quantity

Connector Pin

Quantity

Connection

Note

(1)

DPB

8

6

−

Noise Filter

(2)

DPB

5

3

5

Switching Power Supply (5V)

(3)

DPB

5

3

5

Switching Power Supply (24V)

(4)

DPB

5

3

5

Switching Power Supply (15V)

(5) DPB

26

26<F>

25(D-SUB)

EMERGENCY

(6)

DPB

4

4

8

Switching Power Supply (24V)

(7)

DPB

8

6

8

DMB

(8)

DPB

5

3

5

ProSix Driver Unit I/F Board

*1

(9)

DPB

5

2

5

Regeneration Board

(10)

Regeneration

Board

4

2

−

Regeneration Resistance

(11)

Regeneration

Board

3

2

−

Resistance

(12) DMB

34

34<F>

34

Encoder I/F Board

(13) DMB

4

4

4

Switching Power Supply (15V)

(14) DMB

2

2

2

ProSix Driver Unit I/F Board

*1

(15) CPU Board

50

34<F>

16<F>

34

16

DPB

Encoder I/F Board

(16) CPU Board

4

4

4

Switching Power Supply (5V)

(17) CPU Board

3

3

−

Fan

(18) CPU Board

3

3

−

Fan

(19) CPU Board

2

2

−

Temperature Sensor

(20) CPU Board

80

80<F>

80

Back Plane Board

*3

(21) M/C POWER

50

16

4,4,4,4

DMB

(22) M/C POWER

50

16

14

4,4,4,4

4,4,8

DMB

ProSix Driver Unit I/F Board

*1

<F> Flat cable

*1 When connected to ProSix Driver unit

*3 When connected to Option unit

Summary of Contents for RC180

Page 1: ...Rev 17 EM164C3205F ROBOT CONTROLLER RC180 ...

Page 2: ...ROBOT CONTROLLER RC180 Rev 17 ...

Page 13: ...Safety This section contains information for safety of the Robot System ...

Page 14: ......

Page 20: ......

Page 124: ...Setup Operation 12 Option Units 112 RC180 Rev 17 ...

Page 125: ...Maintenance This section contains maintenance procedures for the Robot Controller ...

Page 126: ...114 ...