Setup & Operation 3. Installation

28

RC180 Rev.17

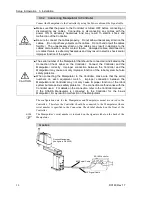

*1 For this connection, only one of the connectors (9) TP cable B or (10) OP cable is

connectable to the TP/OP port.

For details of connection of Operator Panel or Teach Pendant to the TP/OP port, refer

to

Setup & Operation 8.1 What is TP/OP Port?

(1) AC Power terminal block

Terminal block for 200VAC power input to the Controller.

(2) M/C Power cable

The cable with 50-pin connector on the Controller side.

Connect the POWER connector on the Manipulator and the M/C POWER

connector on the Controller. Insert the connectors until you hear a “click”.

(3) M/C Signal cable

The cable with 50-pin connector on the Controller side.

Connect the signal cable to the SIGNAL connector on the Manipulator and the M/C

SIGNAL connector on the Controller.

(4) EMERGENCY

The EMERGENCY connector has inputs to connect the Emergency Stop switch

and the Safety Door switch. For safety reasons, connect proper switches for these

input devices.

For details, refer to the

Setup & Operation 9. EMERGENCY

.

(5) PC for development

Connect the PC for development.

For details, refer to the

Setup & Operation 5. Development PC Port

.

(6) USB memory

Connect the USB memory.

For details, refer to the

Setup & Operation 6. Memory Port

.

(7) LAN (EtherNet Communication)

Connect the EtherNet cable.

For details, refer to the

Setup & Operation 7. LAN (Ethernet Communication) Port

.

(8) I/O connector

This connector is used for input/output devices of the user.

When there are input/output devices, use this connector.

There are I/O cable (option) and terminal block (option) for the I/O connector.

For details, refer to the

Setup & Operation 10. I/O Connector

.

Summary of Contents for RC180

Page 1: ...Rev 17 EM164C3205F ROBOT CONTROLLER RC180 ...

Page 2: ...ROBOT CONTROLLER RC180 Rev 17 ...

Page 13: ...Safety This section contains information for safety of the Robot System ...

Page 14: ......

Page 20: ......

Page 124: ...Setup Operation 12 Option Units 112 RC180 Rev 17 ...

Page 125: ...Maintenance This section contains maintenance procedures for the Robot Controller ...

Page 126: ...114 ...