Setup & Operation 3. Installation

RC180 Rev.17

23

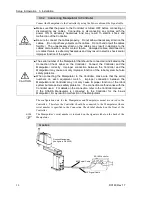

For Controller installation to the Controller box or the base table, process screw hole

drilling as follows.

57.2

76.1

57.2

(1)

(2)

(3)

(4)

(5)

(6)

57.2

76.1

57.2

When mounting direction is (A) or (B)

(1)

90.0

90.0

(2)

(3)

(4)

(5)

(6)

Unit [mm]

8-M5

4-M5

24.7

No screw hole processing is required for mounting direction (D).

Secure it to the rack with screws and nuts.

24.7

20.5

60.0

(Front Side)

20.5

60.0

(Front Side)

When mounting direction is (C) : Fixture S

59.8

59.8

Controller Only

Cont ProSix Driver Unit

No Option Unit

(1) 323 mm

(4) 398 mm

Option Unit

×

1

(2) 378 mm

(5) 453 mm

Option Unit

×

2

(3) 433 mm

(6) 508 mm

- Ensure the draft around the in/out and also install the Controller by keeping the distance

as follows to prevent the nose influence from other equipments such as large contactor

and relay.

Air flow of the Controller Fan

100 mm

100 mm

100 mm

100 mm

Excluding the installation

side such as base table

Summary of Contents for RC180

Page 1: ...Rev 17 EM164C3205F ROBOT CONTROLLER RC180 ...

Page 2: ...ROBOT CONTROLLER RC180 Rev 17 ...

Page 13: ...Safety This section contains information for safety of the Robot System ...

Page 14: ......

Page 20: ......

Page 124: ...Setup Operation 12 Option Units 112 RC180 Rev 17 ...

Page 125: ...Maintenance This section contains maintenance procedures for the Robot Controller ...

Page 126: ...114 ...