Setup & Operation 12. Option Units

RC180 Rev.17

79

12.3 Fieldbus I/O Board

12.3.1 Overview of Fieldbus I/O

The Fieldbus I/O option is an option to add fieldbus slave function (DeviceNet,

PROFIBUS-DP, PROFINET, CC-Link, EtherNet/IP) to the robot Controller.

A fieldbus is a standard of signal communications between field devices operating in a

factory (sensor, actuator, robot controller, etc.) and controller (PLC or robot controller)

using serial communications. Compared to signal communications using analog signals,

a fieldbus has the following features:

a.

Access to signals from multiple devices and multiple data from each device using one

cable.

b.

Precise signal transmission since there is no need for A/D conversion and D/A

conversion.

c.

Less wiring costs, including signal relay board costs and installation area due to several

dozen (or a hundred) devices connected on one fieldbus.

d.

More flexible modification and expansion of a system because multiple devices are

simply added to one fieldbus without additional wiring.

e.

Slave devices can transmit self-diagnostics information.

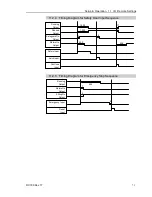

Master Device

RS-232C

RS-232C

Fieldbus

Master Device

Sample Parallel Connection

Sample Fieldbus Connection

Fieldbus slave function can be added to the RC180 Controller. For each fieldbus on the

controller, there is one board installed. You cannot use more than one fieldbus type on

the same controller.

For master device transmission, up to 256 inputs and 256 outputs are available with

Fieldbus I/O.

Response times for Fieldbus I/O can vary and depend on several factors, including baud

rate, scan rate, number and types of devices, number of SPEL+ tasks, etc.

12.3.2 Response Speed of Fieldbus I/O

Fieldbus I/O communicates the I/O status using serial communication. I/O status

exchange lag occurs according to the serial communication speed. This exchange lag is

also influenced by scan cycle, amount and type of the device, and existence of

communication error.

In the RC180 Controller, status of the Fieldbus I/O is updated approximately every 30 mS.

Although the fieldbus communication speed is fast, response is not available for pulses

less than or equal to 30 mS.

NOTE

Summary of Contents for RC180

Page 1: ...Rev 17 EM164C3205F ROBOT CONTROLLER RC180 ...

Page 2: ...ROBOT CONTROLLER RC180 Rev 17 ...

Page 13: ...Safety This section contains information for safety of the Robot System ...

Page 14: ......

Page 20: ......

Page 124: ...Setup Operation 12 Option Units 112 RC180 Rev 17 ...

Page 125: ...Maintenance This section contains maintenance procedures for the Robot Controller ...

Page 126: ...114 ...