Maintenance 1. Safety Precautions on Maintenance

116

RC180 Rev.17

CAUTION

■

Do not touch the Motor Driver modules, Switching Power Supply, and

Regeneration Module directly in the Controller. The metal resistance of these

can become very hot and may result in a burn. If you maintain them, examine

the surface temperatures and wear protective gloves if necessary.

■ Do not shock, shake, or drop any parts during maintenance. When the parts

related with data are shocked physically, they may be damaged and may also

cause data loss during data loading/saving.

■ Do not lose the screws removed at maintenance. When the screw is dropped

into the Controller, be sure to take it out. Leaving the screw in the Controller

may cause short circuit and may result in equipment damage to the parts and/or

robot system.

■ Make sure that the power rating (wattage) of a new Motor Driver module is

correct. Using a Motor Driver module with improper power rating (wattage) in

the Controller may cause improper function of the robot system and errors.

■ The serial number of the Manipulator that should be connected is indicated on

the Connection Check Label on the Controller. Connect the Controller and the

Manipulator correctly. Improper connection between the Controller and the

Manipulator may cause not only improper function of the robot system but also

serious safety problems.

Before performing maintenance on the Controller, all the data must be copied as a backup.

The details of data backup/restore are described in the

Maintenance 4

.

Backup and

Restore.

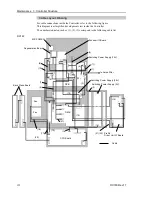

1.2 Lockout / Tagout

Lockout / tagout is a method to prevent any one from turning ON the robot system by

mistake while someone else is within the safeguarded area for maintenance or repair.

When performing maintenance and repair, lockout and tagout using the following

procedure.

(1)

Turn OFF the POWER switch.

(2)

Secure the POWER switch mounting metal hasp in the POWER switch OFF position

with screws.

POWER Switch

Mounting Metal Hasp

POWER Switch

(3)

Unplug the power supply plug of the Controller from the power supply socket.

(4)

Attach a note to the POWER switch or the power supply plug to prevent any one from

turning ON the robot system by mistake.

RC180-UL:

For maintenance and repair, make sure to lockout and tagout the external disconnecting

means.

NOTE

Summary of Contents for RC180

Page 1: ...Rev 17 EM164C3205F ROBOT CONTROLLER RC180 ...

Page 2: ...ROBOT CONTROLLER RC180 Rev 17 ...

Page 13: ...Safety This section contains information for safety of the Robot System ...

Page 14: ......

Page 20: ......

Page 124: ...Setup Operation 12 Option Units 112 RC180 Rev 17 ...

Page 125: ...Maintenance This section contains maintenance procedures for the Robot Controller ...

Page 126: ...114 ...