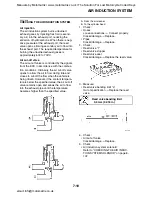

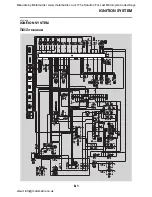

AIR INDUCTION SYSTEM

7-10

EAS27060

CHECKING THE AIR INDUCTION SYSTEM

Air injection

The air induction system burns unburned

exhaust gases by injecting fresh air (second-

ary air) into the exhaust port, reducing the

emission of hydrocarbons. When there is neg-

ative pressure at the exhaust port, the reed

valve opens, allowing secondary air to flow into

the exhaust port. The required temperature for

burning the unburned exhaust gases is

approximately 600 to 700

°

C.

Air cut-off valve

The air cut-off valve is controlled by the signals

from the ECU in accordance with the combus-

tion conditions. Ordinarily, the air cut-off valve

opens to allow the air to flow during idle and

closes to cut-off the flow when the vehicle is

being driven. However, if the coolant tempera-

ture is below the specified value, the air cut-off

valve remains open and allows the air to flow

into the exhaust pipe until the temperature

becomes higher than the specified value.

1. Check:

• Hoses

Loose connections

→

Connect properly.

Cracks/damage

→

Replace.

• Pipes

Cracks/damage

→

Replace.

2. Check:

• Reed valve “1”

• Reed valve stopper

• Reed valve seat

Cracks/damage

→

Replace the reed valve.

3. Measure:

• Reed valve bending limit “a”

Out of specification

→

Replace the reed

valve.

4. Check:

• Air cut-off valve

Cracks/damage

→

Replace.

5. Check

• Air induction system solenoid

Refer to "CHECKING THE AIR INDUC-

TION SYSTEM SOLENOID" on page 8-

102.

A. From the air cleaner

B. To the cylinder head

Reed valve bending limit

0.4 mm (0.016 in)

Manuals by Motomatrix / www.motomatrix.co.uk / The Solution For Lost Motorcycle Coded Keys

email: [email protected]