CRANKSHAFT

5-74

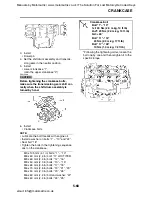

4. Calculate:

• Piston-pin-to-piston-pin-bore clearance

Out of specification

→

Replace the piston

pin and piston as a set.

EAS4C81015

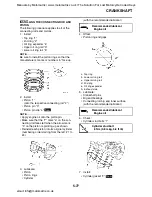

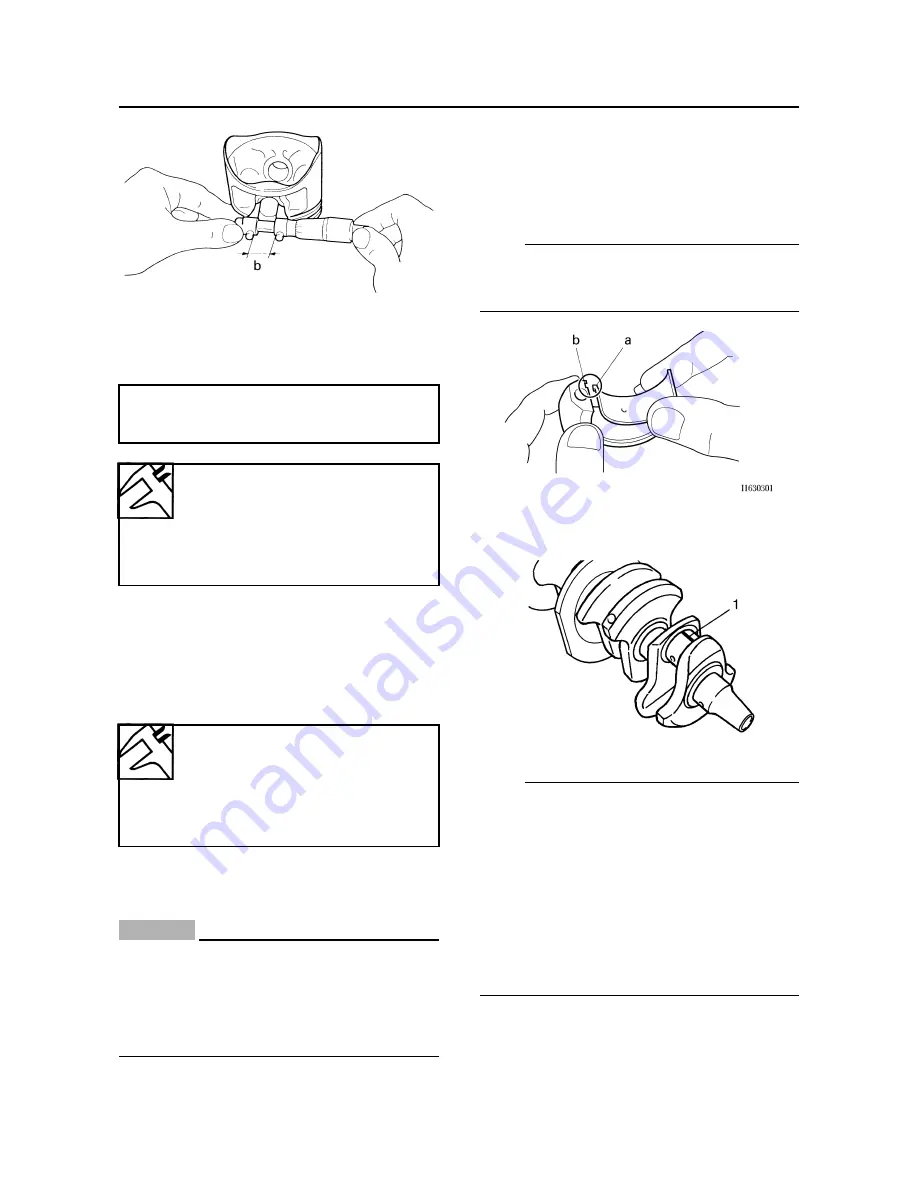

CHECKING THE BIG END BEARINGS

1. Measure:

• Crankshaft-pin-to-big-end-bearing clear-

ance

Out of specification

→

Replace the big end

bearings.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

The following procedure applies to all of the

connecting rods.

CAUTION:

ECA14900

Do not interchange the big end bearings

and connecting rods. To obtain the correct

crankshaft-pin-to-big-end-bearing clear-

ance and prevent engine damage, the big

end bearings must be installed in their orig-

inal positions.

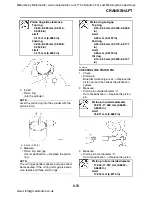

a. Clean the big end bearings, crankshaft

pins, and the inside of the connecting rods

halves.

b. Install the big end upper bearing into the

connecting rod and the big end lower bear-

ing into the connecting rod cap.

NOTE:

Align the projections “a” on the big end bear-

ings with the notches “b” in the connecting rod

and connecting rod cap.

c. Put a piece of Plastigauge® “1” on the

crankshaft pin.

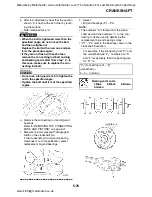

d. Assemble the connecting rod halves.

NOTE:

• Do not move the connecting rod or crank-

shaft until the clearance measurement has

been completed.

• Lubricate the bolt threads with molybdenum

disulfide grease.

• Make sure that the “Y” mark “c” on the con-

necting rod faces towards the left side of the

crankshaft.

• Make sure that the characters “d” on both the

connecting rod and connecting rod cap are

aligned.

Piston-pin-to-piston-pin-bore clearance =

Piston pin bore diameter “b” -

Piston pin outside diameter “a”

Piston-pin-to-piston-pin-bore

clearance

0.002–0.022 mm (0.0001–

0.0009 in)

Limit

0.072 mm (0.0028 in)

Crankshaft-pin-to-big-end-bear-

ing clearance

0.034–0.058 mm

(0.0013–0.0023 in)

Limit

0.09 mm (0.0035 in)

Manuals by Motomatrix / www.motomatrix.co.uk / The Solution For Lost Motorcycle Coded Keys

email: [email protected]