CRANKSHAFT

5-76

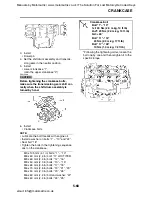

p. After the installation, check that the section

shown “a” is flush with each other by touch-

ing the surface.

• Side machined face “a”

WARNING

EW2D1008

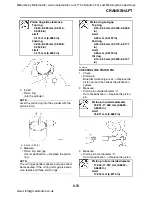

• When the bolt is tightened more than the

specified angle, do not loosen the bolt

and then retighten it.

Replace the bolt with a new one and per-

form the procedure again.

• If they are not flush with each other,

remove the connecting rod bolt and big

end bearing and restart from step “e”. In

this case, make sure to replace the con-

necting rod bolt.

CAUTION:

ECA4C81010

• Do not use a torque wrench to tighten the

nut to the specified angle.

• Tighten the bolt until it is at the specified

angles.

q. Remove the connecting rod and big end

bearings.

Refer to "REMOVING THE CONNECTING

RODS AND PISTONS" on page 5-71.

r.

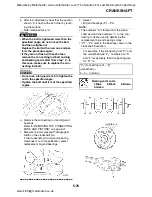

Measure the compressed Plastigauge®

width on the crankshaft pin.

If the crankshaft-pin-to-big-end-bearing

clearance is out of specification, select

replacement big end bearings.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

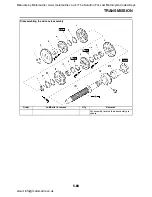

2. Select:

• Big end bearings (P1 – P4)

NOTE:

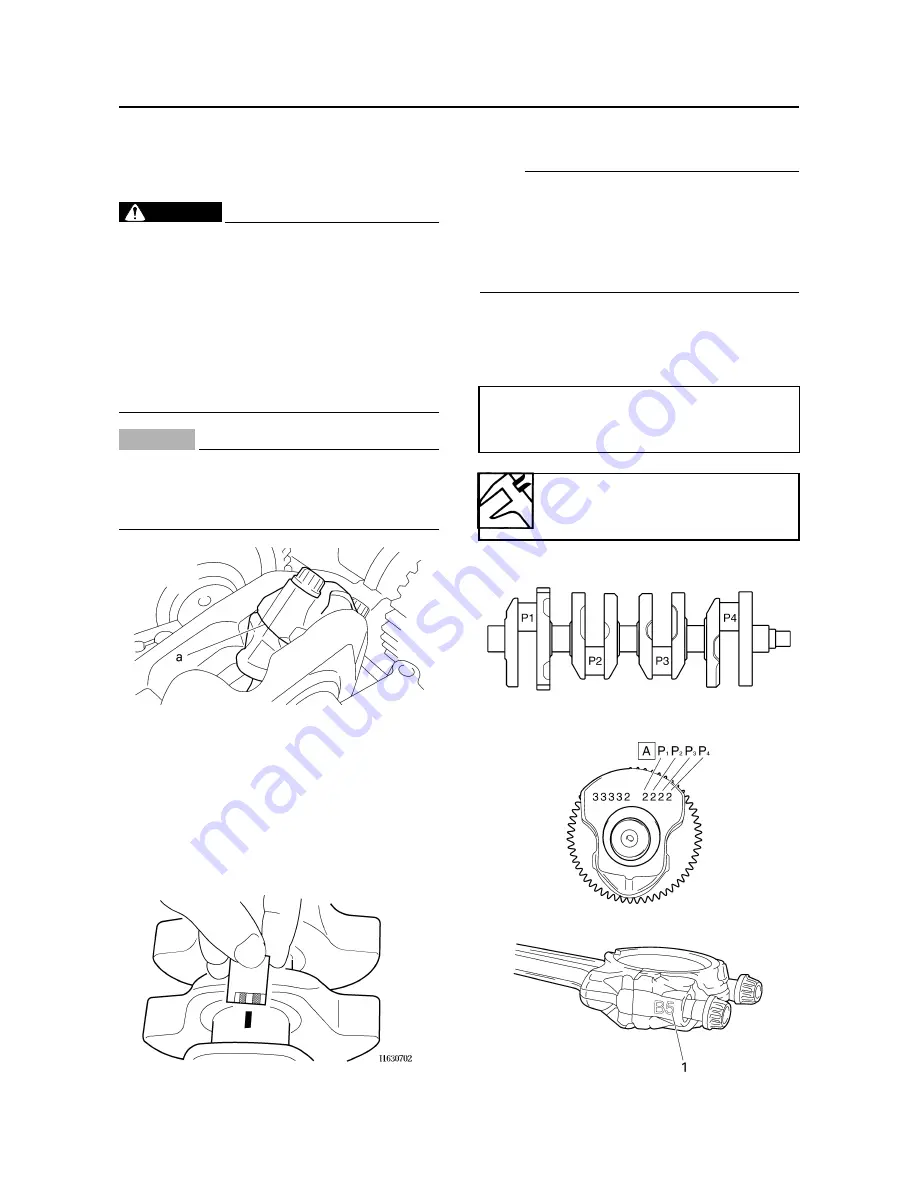

• The numbers “A” stamped into the crank-

shaft wed and the numbers “1” on the con-

necting rods are used to determine the

replacement big end bearings sizes.

• “P1” - ”P4” refer to the bearings shown in the

crankshaft illustration.

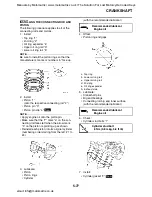

For example, if the connecting rod “P

1

” and

the crankshaft web “P

1

” numbers are “5”

and “2” respectively, then the bearing size

for “P

1

” is:

“P

1

” (connecting rod) – “P

1

”

(crankshaft) =

5 – 2 = 3 (brown)

Bearing color code

1.Blue 2.Black 3.Brown

4.Green

Manuals by Motomatrix / www.motomatrix.co.uk / The Solution For Lost Motorcycle Coded Keys

email: [email protected]