FEATURES

1-5

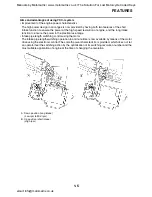

Aims and advantages of using YCC-I system

• Improvement of the engine power characteristics

The high power design in all ranges is now provided by having both two features of the short

intake function to ensure the power at the high speed revolution of engine, and the long intake

function to ensure the power in the practical use range.

• Intake pipe length switching control using the motor

The intake pipe length switching operation in a minute time is now available by means of the motor

drive using the electronic control.The smooth power characteristic is provided, which does not let

an operator feel the switching action by the optimization of its switching revolution number and the

most suitable application of engine at the time of changing the revolution.

A. Down position (long intake)

(Low rpm to Mid rpm)

B. Up position (short intake)

(High rpm)

Manuals by Motomatrix / www.motomatrix.co.uk / The Solution For Lost Motorcycle Coded Keys

email: [email protected]