CRANKCASE

5-68

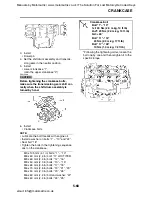

3. Install:

• Dowel pin

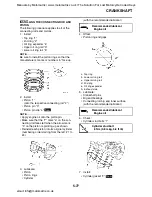

4. Set the shift drum assembly and transmis-

sion gears in the neutral position.

5. Install:

• Lower crankcase “1”

(onto the upper crankcase “2”)

CAUTION:

ECA13980

Before tightening the crankcase bolts,

make sure the transmission gears shift cor-

rectly when the shift drum assembly is

turned by hand.

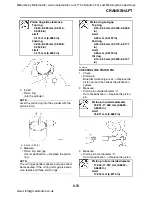

6. Install:

• Crankcase bolts

NOTE:

• Lubricate the bolt threads with engine oil.

• Install a washer on bolts “1” – “10” and “22”.

• Seal bolt “18”

• Tighten the bolts in the tightening sequence

cast on the crankcase.

M9 x 105 mm (4.1 in) bolts: “1” – “10”

M8 x 60 mm (2.4 in) bolt: “11” LOCTITE®

M8 x 60 mm (2.4 in) bolts: “12”, “16”

M8 x 50 mm (2.0 in) bolts: “13” – “15”

M6 x 65 mm (2.5 in) bolts: “17”, “18”

M6 x 70 mm (2.8 in) bolts: “19”, “21”, “23”

M6 x 50 mm (2.0 in) bolts: “20”, “26”

M6 x 60 mm (2.4 in) bolt and washer: “22”

M6 x 60 mm (2.4 in) bolts: “24”, “25”

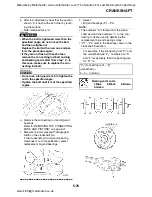

*Following the tightening order, loosen the

bolt one by one and then retighten it to the

specific torque.

Crankcase bolt

Bolt “1”–“10”

1st: 20 Nm (2.0 m·kg, 14 ft·lb)

2nd*: 20 Nm (2.0 m·kg, 14 ft·lb)

3rd: +60

°

Bolt “11”–“16”

24 Nm (2.4 m·kg, 17 ft·lb)

Bolt “17”–“26”

10 Nm (1.0 m·kg, 7.2 ft·lb)

Manuals by Motomatrix / www.motomatrix.co.uk / The Solution For Lost Motorcycle Coded Keys

email: [email protected]