APPENDIX

App. - 32

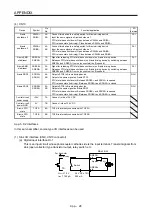

(b) Using a screwdriver

To avoid damaging housings and springs when wiring with screwdriver, do not put excessive force.

Be cautious when connecting.

1) Adjusting screw driver

Diameter: 2.3 mm ± 0.05 mm

Length: 120 mm or less

Width: 2.3 mm

Thickness: 0.25 mm

Angle in tip of the blade: 18 ± 1 degrees

2.3 mm ± 0.05 mm

0.25 mm

2.3 mm

18° ± 1°

Diameter: 2.5 mm ± 0.05 mm

Length: 120 mm or less

Width: 2.5 mm

Thickness: 0.3 mm

Angle in tip of the blade: 12 ± 1 degrees

0.3 mm

2.5 mm

12° ± 1°

2.5 mm ± 0.05 mm

Screwdriver diameter:

φ

2.3 mm

Screwdriver diameter:

φ

2.5 mm

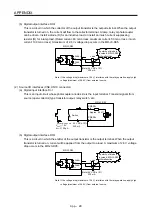

2) Connecting wires

a) Insert a screwdriver in the front slot a little diagonally, and depress the spring. While

depressing the spring, insert the wires until they hit the end. Note that the housing and spring

may be damaged if the screwdriver is inserted strongly. Never insert the screwdriver in the

wire hole. Otherwise, the connector will be damaged.

b) Pull the screwdriver out while pressing the wires. Connecting wires is completed.

c) Pull the wire lightly to confirm that the wire is surely connected.

d) To remove the wires, depress the spring by the screwdriver in the same way as connecting

wires, and then pull the wires out.

Tool insertion slot

Screw driver

Summary of Contents for MR-J4-100B(-RJ)

Page 17: ...8 MEMO ...

Page 143: ...4 STARTUP 4 20 MEMO ...

Page 199: ...5 PARAMETERS 5 56 MEMO ...

Page 227: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 281: ...8 TROUBLESHOOTING 8 16 MEMO ...

Page 303: ...9 DIMENSIONS 9 22 MEMO ...

Page 319: ...10 CHARACTERISTICS 10 16 MEMO ...

Page 429: ...11 OPTIONS AND PERIPHERAL EQUIPMENT 11 110 MEMO ...

Page 435: ...12 ABSOLUTE POSITION DETECTION SYSTEM 12 6 MEMO ...

Page 483: ...14 USING A LINEAR SERVO MOTOR 14 34 MEMO ...

Page 531: ...16 FULLY CLOSED LOOP SYSTEM 16 26 MEMO ...

Page 613: ...17 APPLICATION OF FUNCTIONS 17 82 MEMO ...

Page 654: ...APPENDIX App 41 ...