11. OPTIONS AND PERIPHERAL EQUIPMENT

11 - 29

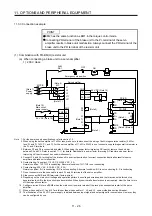

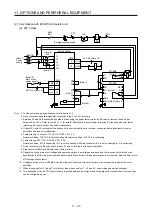

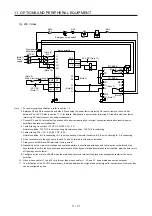

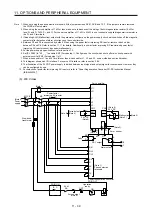

P3

P4

N-

C

Emergency stop switch

Servo amplifier

(Note 11)

(Note 13)

MC

MCCB

(Note 1)

Power

supply

L1

L2

L3

L11

L21

ALM

RA1

OFF

MC

ON

MC

SK

(Note 3)

P+

(Note 2)

(Note 7)

N/-

P/+

BUE

SD

PR

B

C

A

SD

MSG

(Note 4)

(Note 6)

FR-BU2

FR-BR

P

PR

TH2

TH1

(Note 5)

(Note 8)

(Note 10)

Terminal

block

(Note 9)

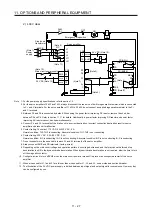

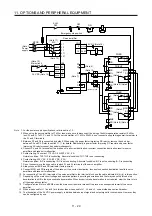

N/-

P/+

BUE

SD

PR

B

C

A

SD

MSG

(Note 4)

(Note 6)

FR-BU2

FR-BR

P

PR

TH2

TH1

(Note 5)

(Note 8)

(Note 9)

CN3

(Note 12)

Main circuit

power supply

24 V DC (Note 14)

5

10

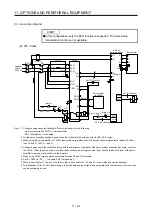

EM2

DICOM

DICOM

20

3

DOCOM

ALM

15

CN3

RA1

24 V DC (Note 14)

Note 1. For the power supply specifications, refer to section 1.3.

2. When using the servo amplifier of 7 kW or less, make sure to disconnect the wiring of built-in regenerative resistor (5 kW or

less: P+ and D, 7 kW: P+ and C). For the servo amplifier of 11 kW to 22 kW, do not connect a supplied regenerative resistor to

the P+ and C terminals.

3. Between P3 and P4 is connected by default. When using the power factor improving DC reactor, remove the short bar

between P3 and P4. Refer to section 11.11 for details. Additionally, a power factor improving DC reactor and power factor

improving AC reactor cannot be used simultaneously.

4. Connect P/+ and N/- terminals of the brake unit to a correct destination. Incorrect connection destination results in servo

amplifier and brake unit malfunction.

5. Contact rating: 1b contact, 110 V AC, 5 A/220 V AC, 3 A

Normal condition: TH1-TH2 is conducting. Abnormal condition: TH1-TH2 is not conducting.

6. Contact rating: 230 V AC, 0.3 A/30 V DC, 0.3 A

Normal condition: B-C is conducting./A-C is not conducting. Abnormal condition: B-C is not conducting./A-C is conducting.

7. Do not connect more than one cable to each P+ and N- terminals of the servo amplifier.

8.

Always connect BUE and SD terminals. (factory-wired)

9. Connect MSG and SD terminals of the brake unit to a correct destination. Incorrect connection destination results in servo

amplifier and brake unit malfunction.

10. For connecting P+ and N- terminals of the servo amplifier to the terminal block, use the cable indicated in (4) (b) in this section.

11. Depending on the main circuit voltage and operation pattern, bus voltage decreases, and that may cause the forced stop

deceleration to shift to the dynamic brake deceleration. When dynamic brake deceleration is not required, slow the time to turn

off the magnetic contactor.

12. Configure a circuit to turn off EM2 when the main circuit power is turned off to prevent an unexpected restart of the servo

amplifier.

13. When wires used for L11 and L21 are thinner than wires used for L1, L2, and L3, use a molded-case circuit breaker.

14. The illustration of the 24 V DC power supply is divided between input signal and output signal for convenience. However, they

can be configured by one.

Summary of Contents for MR-J4-100B(-RJ)

Page 17: ...8 MEMO ...

Page 143: ...4 STARTUP 4 20 MEMO ...

Page 199: ...5 PARAMETERS 5 56 MEMO ...

Page 227: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 281: ...8 TROUBLESHOOTING 8 16 MEMO ...

Page 303: ...9 DIMENSIONS 9 22 MEMO ...

Page 319: ...10 CHARACTERISTICS 10 16 MEMO ...

Page 429: ...11 OPTIONS AND PERIPHERAL EQUIPMENT 11 110 MEMO ...

Page 435: ...12 ABSOLUTE POSITION DETECTION SYSTEM 12 6 MEMO ...

Page 483: ...14 USING A LINEAR SERVO MOTOR 14 34 MEMO ...

Page 531: ...16 FULLY CLOSED LOOP SYSTEM 16 26 MEMO ...

Page 613: ...17 APPLICATION OF FUNCTIONS 17 82 MEMO ...

Page 654: ...APPENDIX App 41 ...