16. FULLY CLOSED LOOP SYSTEM

16 - 11

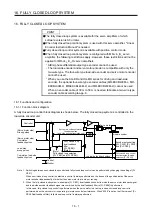

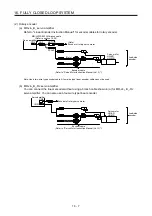

(3) Selection of load-side encoder communication method

The communication method changes depending on the load-side encoder type. Refer to table 1.1 and

"Linear Encoder Instruction Manual" for the communication method for each load-side encoder.

Select the cable to be connected to CN2L connector in [Pr. PC26].

0 0 0

[Pr. PC26]

Load-side encoder cable communication method selection

0: Two-wire type

1: Four-wire type

When using a load-side encoder of A/B/Z-phase differential output method, set "0".

Incorrect setting will trigger [AL. 70] and [AL. 71]. Setting "1" while

using a servo amplifier other than MR-J4-_B_-RJ will trigger [AL. 37].

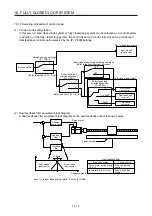

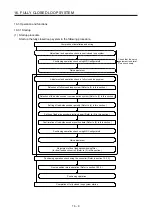

(4) Setting of load-side encoder polarity

CAUTION

Do not set an incorrect direction to "Encoder pulse count polarity selection" in [Pr.

PC27]. An abnormal operation and a machine collision may occur if an incorrect

direction is set, which cause a fault and parts damaged.

POINT

"Encoder pulse count polarity selection" in [Pr. PC27] is not related to [Pr. PA14

Rotation direction selection]. Make sure to set the parameter according to the

relationships between servo motor and linear encoder/rotary encoder.

Do not set an incorrect direction to "Encoder pulse count polarity selection" in

[Pr. PC27]. Doing so may cause [AL. 42 Fully closed loop control error] during

the positioning operation.

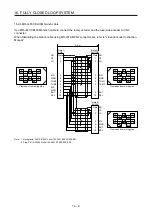

(a) Parameter setting method

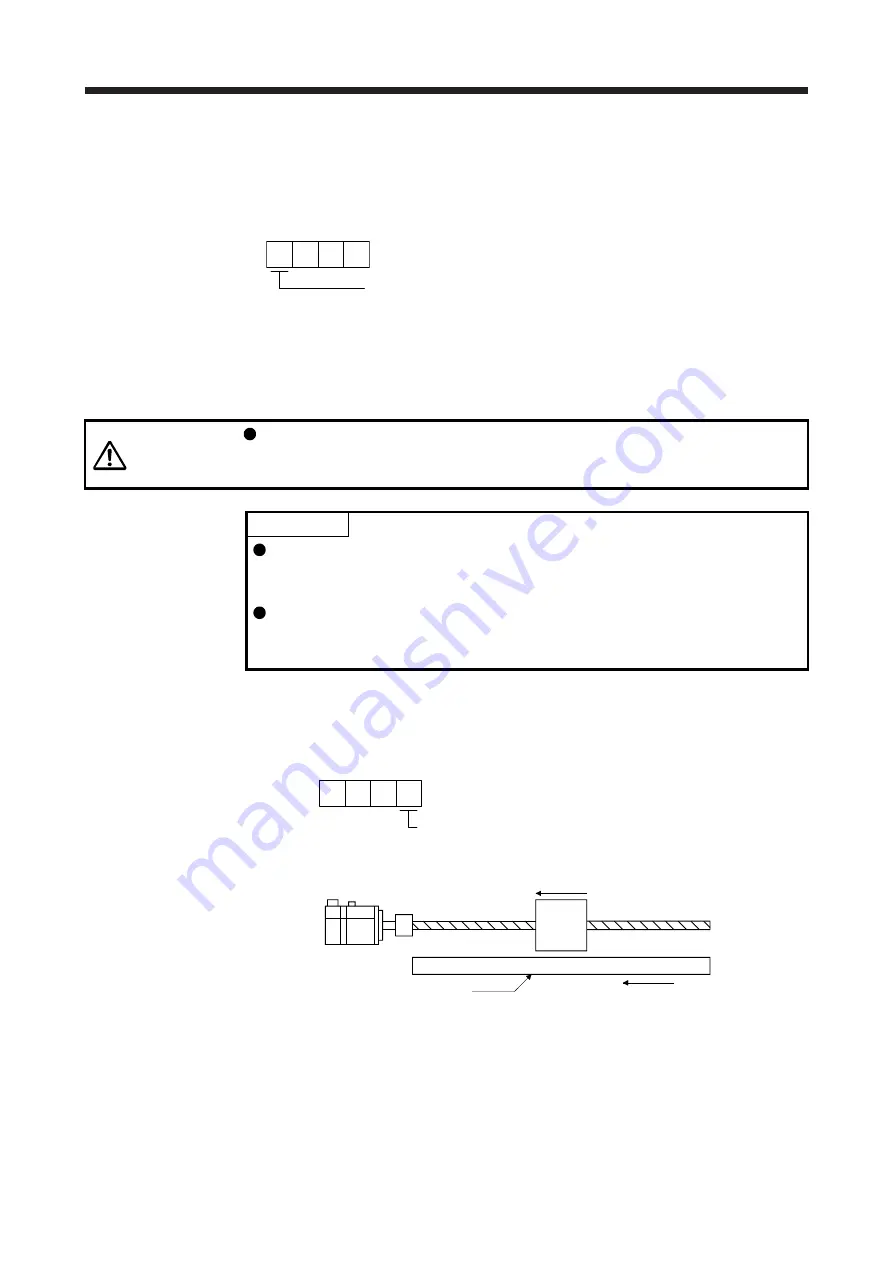

Set the load-side encoder polarity to be connected to CN2L connector in order to match the CCW

direction of servo motor and the increasing direction of load-side encoder feedback.

0 0 0

[Pr. PC27]

Encoder pulse count polarity selection

0: Load-side encoder pulse increasing direction in the servo motor CCW

1: Load-side encoder pulse decreasing direction in the servo motor CCW

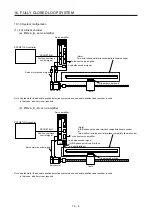

Servo motor

Linear encoder

Servo motor CCW direction

Address increasing direction of linear encoder

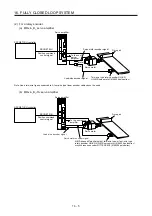

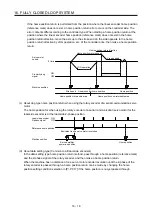

(b) How to confirm the load-side encoder feedback direction

For the way of confirming the load-side encoder feedback direction, refer to (6) in this section.

Summary of Contents for MR-J4-100B(-RJ)

Page 17: ...8 MEMO ...

Page 143: ...4 STARTUP 4 20 MEMO ...

Page 199: ...5 PARAMETERS 5 56 MEMO ...

Page 227: ...6 NORMAL GAIN ADJUSTMENT 6 28 MEMO ...

Page 281: ...8 TROUBLESHOOTING 8 16 MEMO ...

Page 303: ...9 DIMENSIONS 9 22 MEMO ...

Page 319: ...10 CHARACTERISTICS 10 16 MEMO ...

Page 429: ...11 OPTIONS AND PERIPHERAL EQUIPMENT 11 110 MEMO ...

Page 435: ...12 ABSOLUTE POSITION DETECTION SYSTEM 12 6 MEMO ...

Page 483: ...14 USING A LINEAR SERVO MOTOR 14 34 MEMO ...

Page 531: ...16 FULLY CLOSED LOOP SYSTEM 16 26 MEMO ...

Page 613: ...17 APPLICATION OF FUNCTIONS 17 82 MEMO ...

Page 654: ...APPENDIX App 41 ...