2.4 Driver Unit/Simple Absolute Unit Alarm Causes and Countermeasures

C2-21

ME0384-4A

M

ai

nt

ena

nc

e

Sec

tion

C

ha

pt

er

2

Tr

oubl

es

hoot

in

g

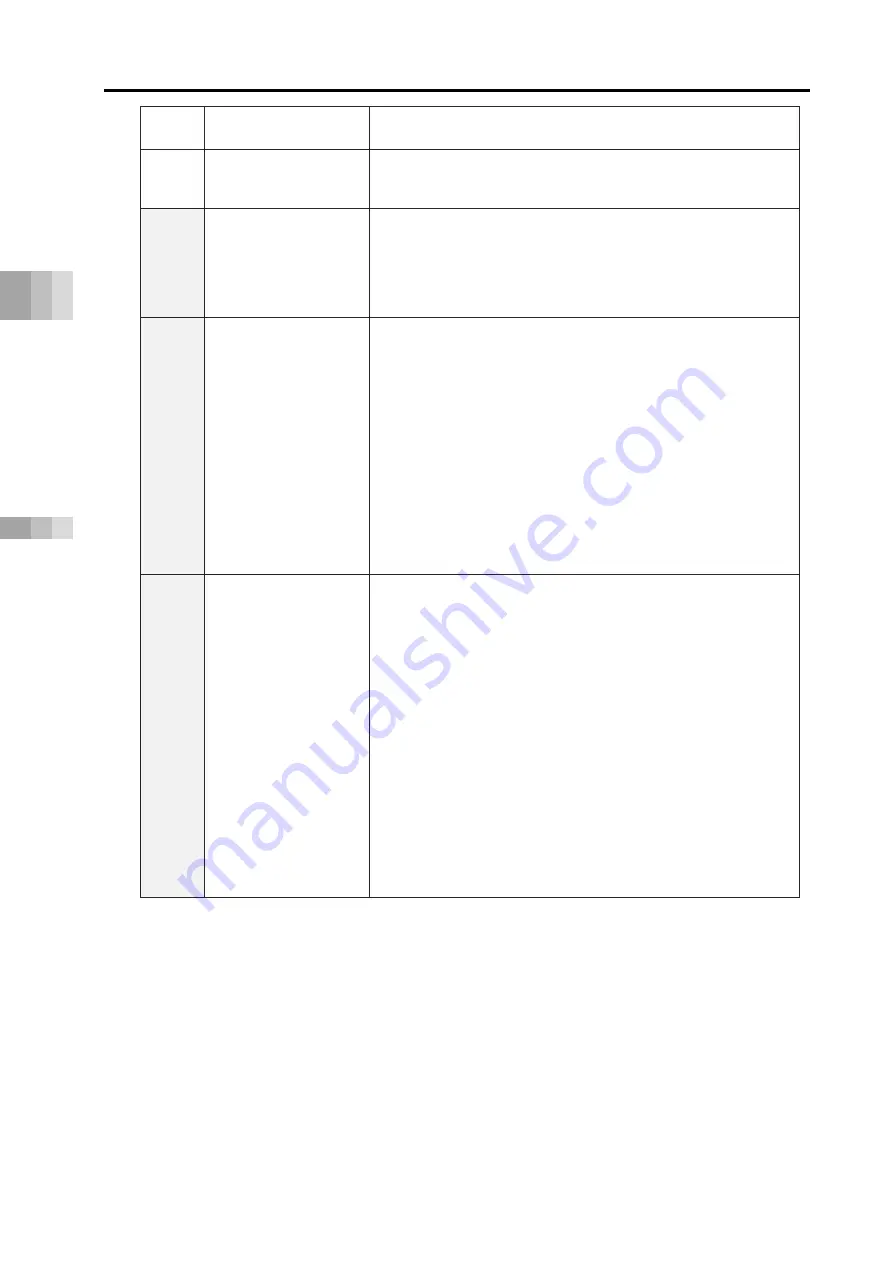

Alarm

code

Alarm name

Causes/countermeasures

0A8

Motor/encoder type not

supported

Cause: A motor or encoder type not supported by this driver unit is connected.

Countermeasure: Contact IAI if this alarm is generated with an actuator

being controlled, or in case it reoccurs even after reboot.

0B3

S

Driver

limited

Spurious absolute error

Cause: Home-return operation was not performed properly.

1) Work is interfering with peripheral equipment in the middle

of home return.

2) Encoder Error

Countermeasure: 1) Remove the interference.

2) Please contact IAI.

0B4

A

Driver

limited

Electrical angle mismatch

(inconsistency)

Cause: An error was detected during the electromagnetic phase detection

operation when the servo was turned on after the power was supplied.

<When detail code is 0000H>

Position deviation counter has overflown before Z-axis was detected.

1) Operation unable due to external force

2) Sliding resistance on actuator itself is high

<When detail code is 0001H>

Z-phase was detected two times before the motor makes one turn.

3) Malfunction of encoder PCB or disc

Countermeasure: 1) Check if there is any failure in actuator installation.

2) If the payload is in normal condition, shut off the

power and move the slider manually with hand to

see the sliding resistance.

In case there is a cause on the actuator, contact IAI.

3) The motor requires to be replaced. Contact IAI.

0B7

A

Driver

limited

Magnetic pole uncertain

Cause: When magnetic pole phase detection (carried out even with

simple absolute specification) was performed in the first servo

ON process after power ON, magnetic pole phase could not be

detected after a given period of time.

1) Contact failure or disconnection of the connector part of the

actuator connecting cable.

2) For models with brake, the brake cannot be released.

3) External force is applied and the motor cannot perform detection.

4) The sliding resistance of the actuator itself is excessive.

Countermeasure: 1) Check the wiring status of the actuator connecting cable.

2) Check the wiring condition of the brake cable and

whether the brake part makes "clicking" sounds

when toggling the brake release switch. If not,

confirm that power is supplied to the brake.

3) Confirm that there are no assembly errors.

4) If the loading weight is normal, turn OFF the

power and then move by hand to check the

sliding resistance.

If the cause is in the actuator itself, contact IAI.

Summary of Contents for Rcon

Page 12: ...ME0384 4A ...

Page 32: ...Actuator Coordinate System Intro 20 ME0384 4A ...

Page 42: ...1 3 General Specifications A1 9 ME0384 4A Specifications Section Chapter 1 RCON Overview ...

Page 45: ...ME0384 4A ...

Page 291: ...ME0384 4A ...

Page 323: ...ME0384 4A ...

Page 384: ...1 3 Startup Procedure B1 9 ME0384 4A Startup Section Chapter 1 Overview ...

Page 420: ...3 6 Precautions B3 15 ME0384 4A Startup Section Chapter 3 Absolute Reset ...

Page 588: ...6 2 Various Functions B6 81 ME0384 4A Startup Section ...

Page 837: ......

Page 838: ......