14. USING A DIRECT DRIVE MOTOR

14 - 52

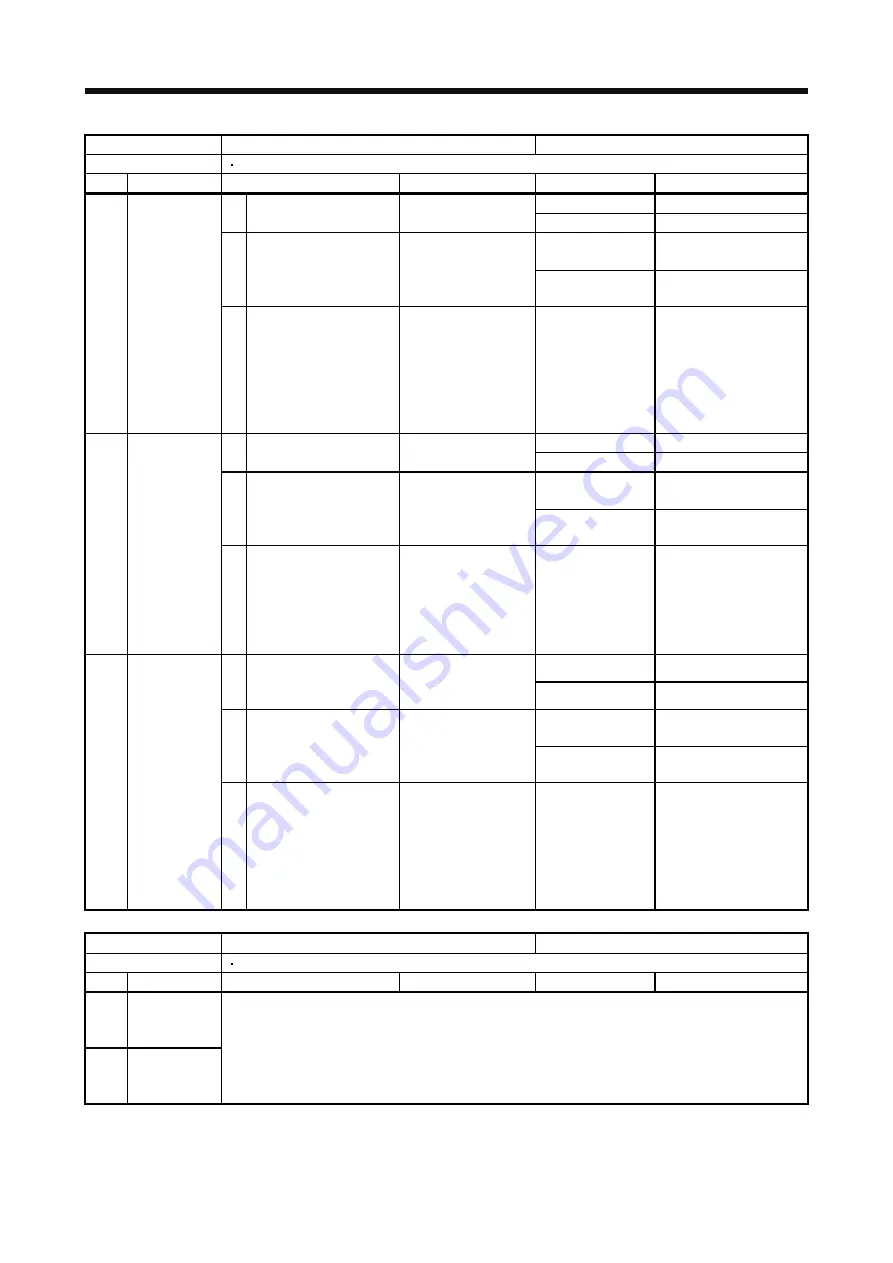

Alarm No.: 42

Name: Servo control error

Stop system: Each axis

Alarm content

A servo control error occurred.

Display

Detail name

Cause

Check method

Check result

Action

42.1

Problem found.

Wire it correctly.

1) Connection of the direct

drive motor is not correct.

Check the wiring.

No problem found.

Check 2).

Servo control

error by position

deviation

It is not repeatable.

Execute the magnetic pole

detection.

2) The initial magnetic pole

detection was not

executed.

Execute the magnetic

pole detection again,

and then check the

repeatability.

It is repeatable.

Check 3).

3) The position deviation

reached the detection level.

Check the operation

status.

(Check the value of

droop pulses.)

The deviation is

large.

Review the operation

status.

Review the setting of

parameter No.PS05 (Servo

control position deviation

error detection level) as

required.

42.2

Problem found.

Wire it correctly.

1) Connection of the direct

drive motor is not correct.

Check the wiring.

No problem found.

Check 2).

Servo control

error by speed

deviation

It is not repeatable.

Execute the magnetic pole

detection.

2) The initial magnetic pole

detection was not

executed.

Execute the magnetic

pole detection again,

and then check the

repeatability.

It is repeatable.

Check 3).

3) The speed deviation

reached the detection level.

Check the operation

status.

(Calculate the deviation

between the speed

command and direct

drive motor speed.)

The deviation is

large.

Review the operation

status. Review the setting

of parameter No.PS06

(Servo control speed

deviation error detection

level) as required.

42.3

Problem found.

Wire it correctly.

Servo control

error by torque

detection

1) Connection of the direct

drive motor is not correct.

Check the wiring.

No problem found.

Check 2).

It is not repeatable.

Execute the magnetic pole

detection.

2) The initial magnetic pole

detection was not

executed.

Execute the magnetic

pole detection again,

and then check the

repeatability.

It is repeatable.

Check 3).

3) The thrust deviation

reached the detection level.

Check the operation

status.

(Calculate the deviation

between the current

command and torque.)

The deviation is

large.

Review the operation

status.

Review the setting of

parameter No.PS07 (Servo

control torque deviation

error detection level) as

required.

Alarm No.: 45

Name: Main circuit device overheat

Stop system: All axes

Alarm content

Inside of the servo amplifier overheated.

Display

Detail name

Cause

Check method

Check result

Action

45.1 Main

circuit

device overheat

error

45.5 Board

temperature

error

Same as for the rotary servo motors.

Refer to section 8.3.

Summary of Contents for MELSERVO-J3W Series

Page 17: ...8 MEMO ...

Page 27: ...1 FUNCTIONS AND CONFIGURATION 1 10 MEMO ...

Page 87: ...4 STARTUP 4 14 MEMO ...

Page 117: ...5 PARAMETERS 5 30 MEMO ...

Page 129: ...6 GENERAL GAIN ADJUSTMENT 6 12 MEMO ...

Page 185: ...10 CHARACTERISTICS 10 8 MEMO ...

Page 241: ...11 OPTIONS AND AUXILIARY EQUIPMENT 11 56 MEMO ...

Page 274: ...13 USING A LINEAR SERVO MOTOR 13 25 1 2 3 4 ...