GSK988TA/GSK988TA1/GSK988TB Turning Center CNC System User Manual

【

Programming & Operation

】

304

Ⅱ

Operation

cursor is. After the program running ends, M02 program end code is executed and the cursor doesn’t

return the program ahead; while M30 program end code is executed, the cursor is returned to the

program ahead, after the program running ends, the system enters the stopping status.

(

4

)

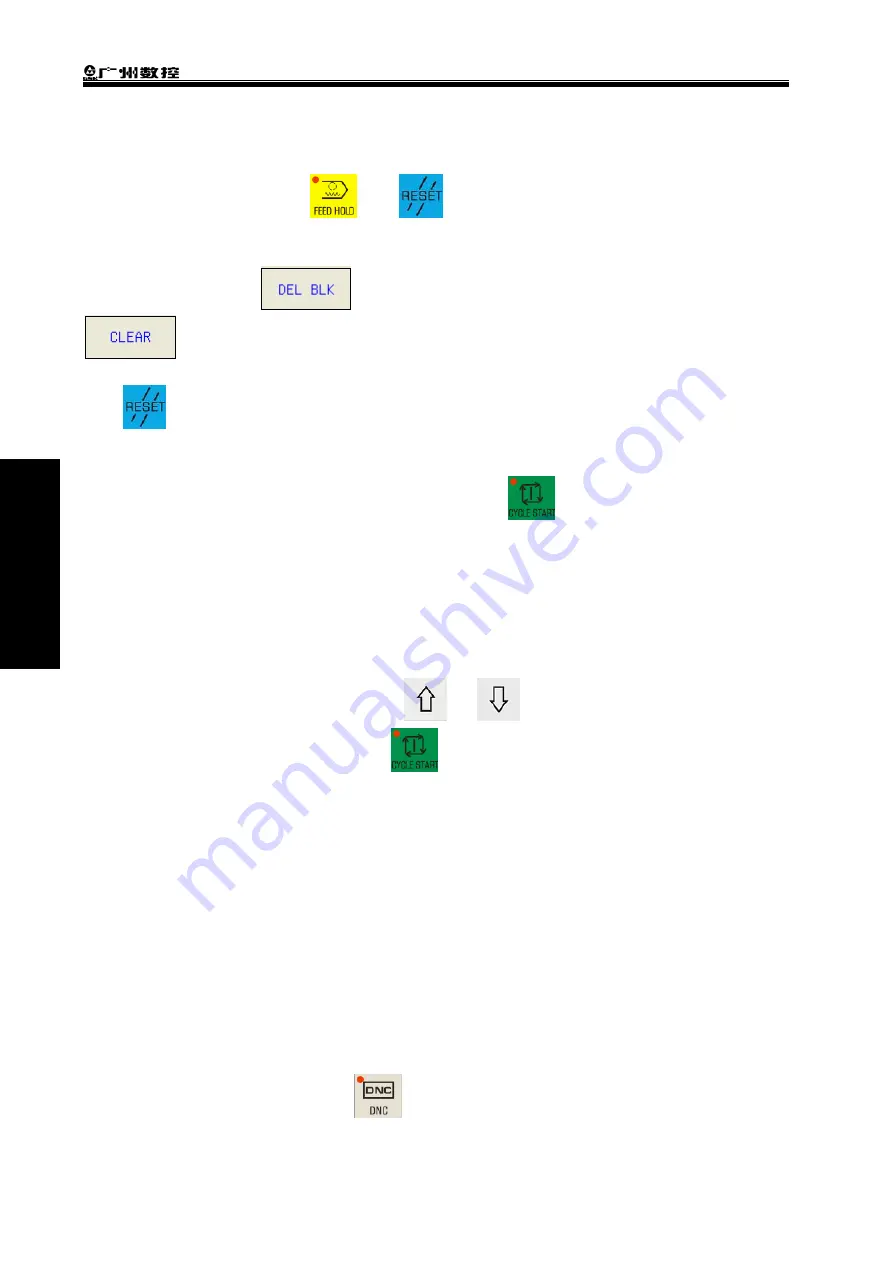

During running, press

key,

key and the emergency stop button to make MDI

command word stop running.

Note 1: Deleting the program

a. In MDI mode, press

software key to delete the block on which the cursor is and press

software key to delete all blocks in MDI edit column.

b. When parameter MCL

(

NO.3203#7

)

is set as 1, the program is automatically cleared after pressing

key.

c. When parameter MER

(

NO.3203#6

)

is set as 1, MDI program running is completed and deleted in MDI

mode.

Note 2: When MDI running stops, after edit operation ends,

is

pressed for running, again, the

running is started from the position on which the current cursor is.

Note 3: The program created in MDI mode can’t be stored.

Note 4: The sub-program calling and macro program calling functions can not be performed in the MDI

mode.

6.2.2 Running from Arbitrary Block

On position display page, in MDI mode,

or

key is pressed to move the cursor to

the block to be started running, and then

is pressed to start the program, the program is

executed from the block on which the cursor is.

6.2.3 Stopping MDI Operation

Stopping MDI running is similar with stopping automatic running, please refer to the operation

method in Chapter 6.1.4.

6.3 DNC Running

GSK988TA/988TA1/988TB is with DNC function, and DNC communication software can be

connected with CNC to realize the running at high speed and with the big capacity.

After the machine tool panel key

is pressed to enter DNC mode, and PC port is ready,

and the machine tool panel cycle start key is pressed to start the program DNC machining.

Summary of Contents for GSK988TA

Page 6: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation VI ...

Page 19: ...1 Ⅰ Programming PROGRAMMING ...

Page 227: ...209 Ⅱ Operation OPERATION ...

Page 369: ...Chater 10 Machining Example 351 Ⅱ Operation ...

Page 371: ...353 Appendix ...

Page 465: ...Appendix 1 Parameters 447 Appendix ...

Page 479: ...Appendix 3 Interface Explanation 461 Appendix ...

Page 527: ...Appendix 5 Installation Layout 509 Appendix ...