IO-390-D Series Engine Maintenance Manual

72-30

© 2020 Avco Corporation. All Rights Reserved

Page 226

March 2020

IO-390-D Series Engine Maintenance Manual

W.

Lubricate rocker contact surfaces with Modoc

®

Oil 175.

NOTICE:

If a cork rocker box cover gasket is installed, torque the rocker box cover screws to

50 in.-lb. (5.6 Nm). Do not reuse cork gaskets.

X.

Examine the silicone rocker box cover gasket to make sure it is intact and not deformed or

damaged. Replace as necessary.

Y.

Install the silicone rocker box cover gasket and rocker box cover with screws on each rocker

box. Torque the screws to 35 in.-lb. (4.0 Nm).

Z.

Remove the vented plug from each spark plug hole.

AA.

Install the top and bottom spark plugs as per the section “Spark Plug Installation” in Chapter

74-20.

AB. Remove the caps from the fuel line and fuel injection nozzle and reconnect the fuel line to

the injection nozzle. Refer to the latest revision of the Service Table of Limits - SSP-1776

for torque values.

AC. Install the clamps that attach the fuel line to the shroud tube per instructions in the latest

revision of Service Bulletin No. SB-342.

AD. Install the applicable intake pipe on the cylinder per the “Intake Pipe Installation” procedure

in Chapter 72-80. Install the applicable exhaust pipe on the cylinder per the airframe

manufacturer’s instructions.

AE. Intercylinder Baffle Installation

(1)

Engage the "S-Type" retaining hook (Figure 3) through the hole in the baffle.

(2)

Put the baffle in position beneath and between the cylinders and turn the hook up between

the cylinder barrels.

(3)

Put a baffle retainer in place between the cylinders and bring the retainer hook through

the slot in the retainer. The retainer is forced down until the hook is above the surface of

the retainer far enough to be engaged over the bridge between the slots in the retainer.

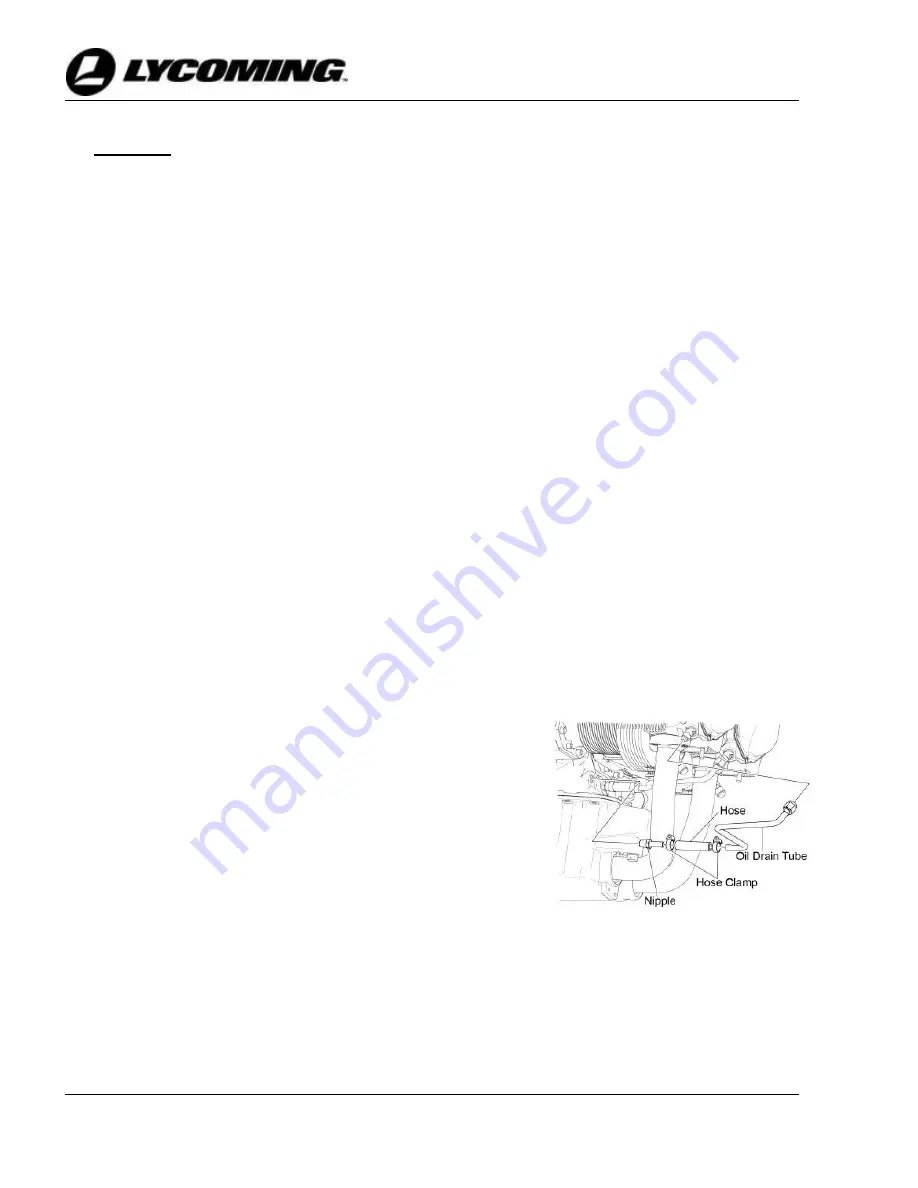

AF. Oil Drain Tube Installation

(1)

Connect a new hose to the nipple (Figure 38) in the

crankcase.

(2)

Install and tighten a hose clamp on the hose closest to

the crankcase.

(3)

Connect the oil drain tube to the elbow at the cylinder

with a flange nut. Torque the nut per the latest

revision of the

Service Table of Limits - SSP-1776.

(4)

Connect the new hose to the drain tube assembly.

(5)

Install and tighten a hose clamp on the hose and oil

drain tube connection.

(6)

Torque both hose clamps per the Special Torque

Requirements Tables in Part 1, Section V in the latest

revision of the

Service Table of Limits - SSP-1776

.

Figure 38

Oil Drain Tube

AG. Connect the correct ignition lead to each spark plug per the section “Ignition Harness

Installation” in Chapter 74-20.

AH. Complete the “Oil Change Procedure” in Chapter 12-10.