IO-390-D Series Engine Maintenance Manual

74-30

© 2020 Avco Corporation. All Rights Reserved

Page 282

March 2020

IO-390-D Series Engine Maintenance Manual

NOTICE:

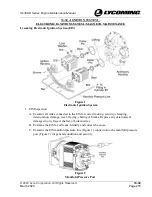

The drive gear fits on the EIS shaft in one of two orientations. A normal

installation (Figure 5) will align a gear tooth valley with the woodruff

key on the EIS shaft.

If you have difficulty timing the EIS to the engine in further steps, it may

be necessary to remove the drive gear from the EIS and re-install it 180°

on the shaft as shown in the alternate orientation (Figure 6)

(a)

Install the drive gear (magneto gear) on the EIS driveshaft in the normal

orientation (Figure 5).

Figure 5

Normal Drive Gear Orientation

Figure 6

Alternate Drive Gear Orientation

(b)

Remove excess anti-seize compound from the EIS driveshaft.

(c)

Place the washer under castellated nut and thread nut onto shaft.

(d)

Torque the castellated nut to 120 to 180 in.-lbs. (14 to 20 Nm). Tighten to align

the castellated nut to the hole in the shaft. Do not exceed 250 in.-lbs. (28 Nm).

(e)

Install a new cotter pin through the nut and EIS driveshaft. Bend the top prong on

the cotter pin over the driveshaft and bend the bottom prong of the cotter pin

down.

(f)

Ensure locked cotter pin end does not extend beyond the forward face of the drive

gear.

(2)

Internally Time the EIS:

You must internally time the EIS to align the drive gear before installing the EIS.

(a)

Connect a temporary source of positive (+)

8.5 – 30VDC power to the terminal

labelled TIMING (Figure 7) on the EIS

using the provided screw. Finger tighten

the screw.

Figure 7

Timing Terminal and EIS LED