IO-390-D Series Engine Maintenance Manual

72-00

© 2020 Avco Corporation. All Rights Reserved

Page 104

March 2020

IO-390-D Series Engine Maintenance Manual

4.

Operational Ground Check

NOTICE:

The purpose of this check is to make sure the installed engine operates in the aircraft

according to specifications in Appendix A of the

IO-390-D Series Engine Installation

and Operation Manual

.

A.

Per the component manufacturer's instructions, calibrate the cylinder head temperature gage,

oil temperature gage, oil pressure gage, manifold pressure gage, and tachometer prior to

testing.

B.

Make sure that all of the engine gages operate correctly.

C.

Make sure that the vent and breather lines are correctly installed and secured in accordance

with the aircraft manufacturer’s instructions.

D.

Install the cowling and all of the aircraft baffles per the aircraft manufacturer’s instructions.

E.

Position the aircraft into the wind.

F.

Complete the applicable procedures in either the “Engine Initiation” chapter or “Engine

Operation” chapter of the

IO-390-D Series Engine Installation and Operation Manual.

NOTICE:

Engine initiation procedures are to be done in the field on any of the following

newly installed Lycoming engines:

•

Any new, overhauled, or rebuilt engine from the factory and field-overhauled engines

•

Engine taken out of storage (if not run-in when put in storage)

•

An engine which has been disassembled/re-assembled

5.

Idle Speed and Mixture Adjustment

NOTICE:

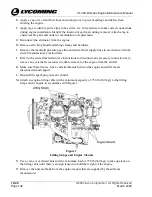

The fuel injector servo has a speed

adjustment screw to adjust the idle

speed. Refer to Figure 2. There is

also a mixture adjustment wheel on

the throttle body to adjust the idle

mixture. Refer to Figure 2.

NOTICE:

The goal of this procedure is to

adjust the idle speed and mixture to

an optimum level.

A.

Start the engine and operate it until the oil

and cylinder head temperatures are in the

specified operating range shown in

Appendix A of the

IO-390-D Series

Engine Installation and Operation

Manual

.

Figure 2

Speed Adjustment Screw and Mixture

Adjustment Wheel on the Fuel Injector Servo

B.

Set the throttle stop screw to let the engine idle at idling rpm speed.

NOTICE:

As needed, set fuel controls on new, rebuilt, or overhauled engine to 50 to 100 rpm

higher than usual idle speed (600 to 700 rpm) for the first 25 hours of operation -

then adjust to the usual setting after the first 25 hours of operation.