IO-390-D Series Engine Maintenance Manual

72-20

© 2020 Avco Corporation. All Rights Reserved

Page 142

March 2020

IO-390-D Series Engine Maintenance Manual

Crankshaft Inspection Checklist for IO-390-D Series Engines (Cont.)

CAUTION

LYCOMING ENGINES NO LONGER APPROVES STRAIGHTENING OR

GRINDING OF BENT CRANKSHAFT FLANGES TO RESTORE

MAXIMUM RUN-OUT. IF THE CRANKSHAFT FLANGE IS BENT,

REPLACE THE CRANKSHAFT. DO NOT TRY TO STRAIGHTEN OR

GRIND THE CRANKSHAFT FLANGE. (REFER TO THE LATEST

REVISION OF SERVICE BULLETIN NO. SB-201)

Item

Comments

Findings/

Corrective Action

Done

Measure the crankshaft flange

thickness and compare it with the

dimensions below to calculate the

minimum permissible thickness.

If the crankshaft flange is

bent, replace the crankshaft.

Do NOT straighten or grind

a bent crankshaft. Refer to

the latest revision of Service

Bulletin No. 201 for any

additional details.

Crankshaft Flange Thickness

Inches

Millimeters

Inches

Millimeters

0.440 ± 0.010

11.176 ± 0.254

0.420

10.668

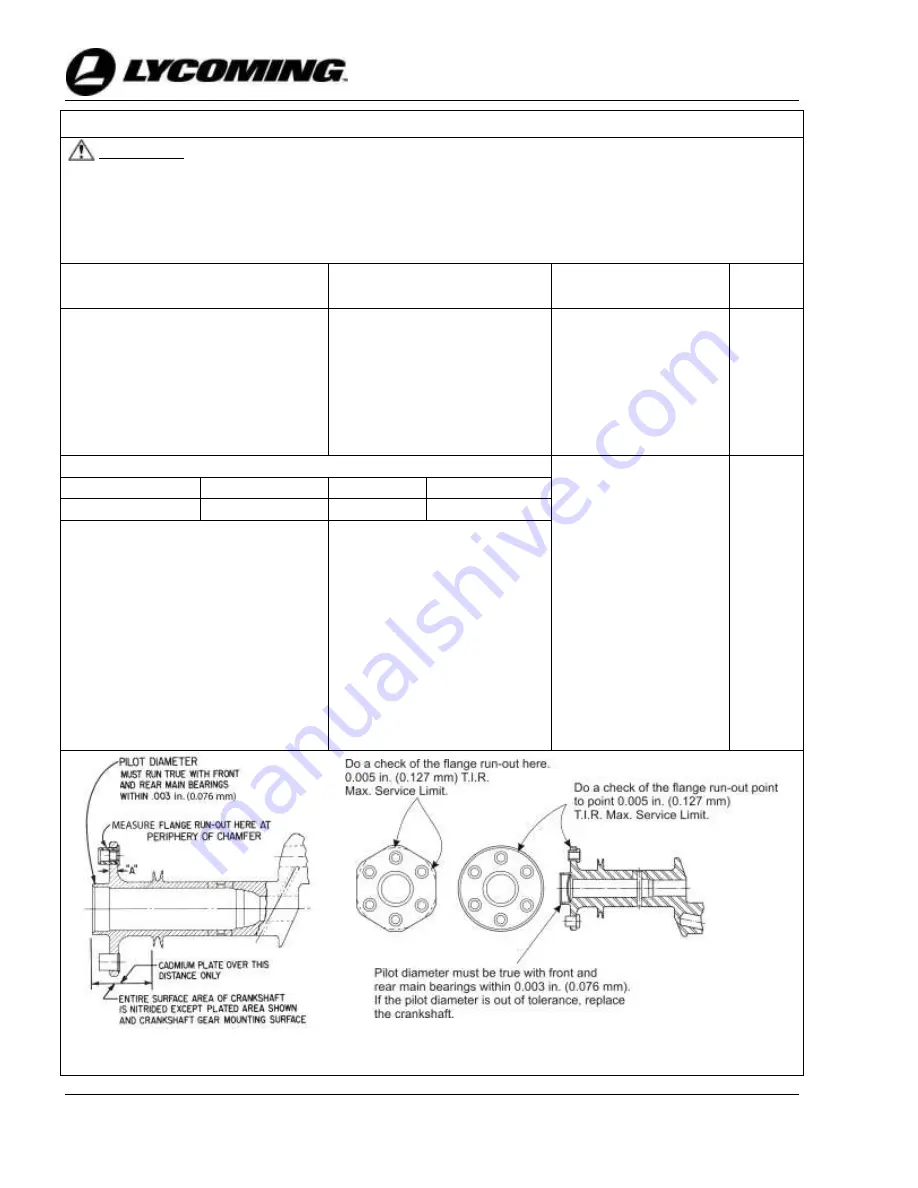

Measure the run-out of the

crankshaft flange with a dial

indicator at the location shown in

Figures 25 and 26. The maximum

Total Indicator Reading (TIR)

must not be more than 0.005 in.

(0.127 mm). As shown in Figure

25, make sure that the pilot

diameter runs true with the front

and rear main bearings within

0.003 in. (0.076 mm).

If run-out exceeds 0.002 in.

(0.051 mm) total indicator

reading, replace the

crankshaft.

Do not try to repair or grind

a warped or bent crankshaft

flange.

Figure 25

Crankshaft Flange

Figure 26

Crankshaft Flange Run-out and Pilot Diameter

Measure the front face of the

crankshaft flange between the

flange bushings and the edge

of the chamfer.