IO-390-D Series Engine Maintenance Manual

72-20

© 2020 Avco Corporation. All Rights Reserved

Page 146

March 2020

IO-390-D Series Engine Maintenance Manual

Crankshaft Inspection Checklist for IO-390-D Series Engines (Cont.)

Item

Comments

Findings/

Corrective Action

Done

Examine the gear mounting

face of the crankshaft

counterbore.

If the mounting face of the

crankshaft counterbore is

damaged, replace the crankshaft.

If there is a hole or tang on the

crankshaft gear (instead of a

slot), examine the tang for any

nicks or dents.

If nicks or dents are found,

replace the crankshaft gear with

a new three-scallop pilot flange

gear (Figure 28).

Examine and measure the

alignment dowel per

instructions in the “Alignment

Dowel Inspection” in this

chapter.

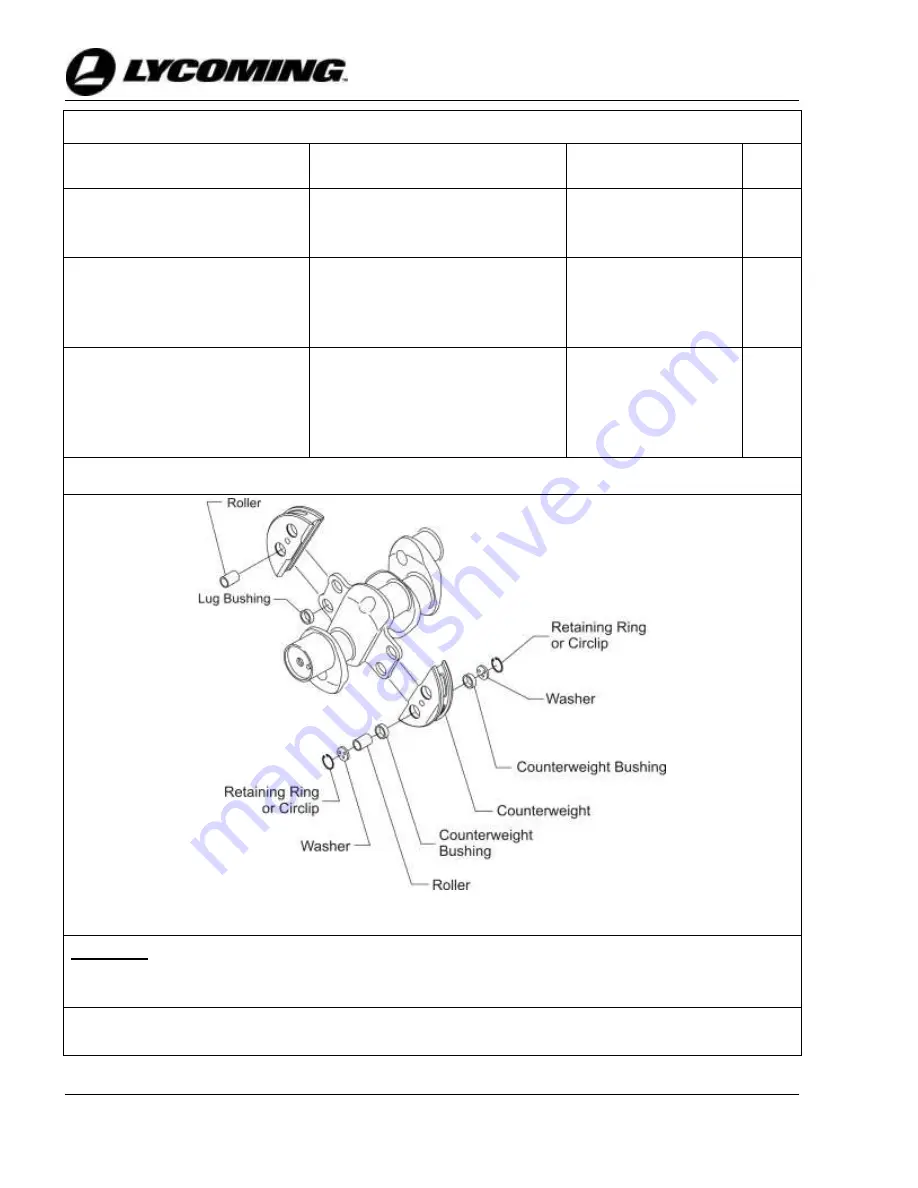

Counterweight Inspection

Figure 30

Crankshaft Counterweight, Rollers, and Bushings

NOTICE:

A crankshaft counterweight (Figure 30) cannot be repaired. It only can be replaced.*

A counterweight roller cannot be repaired. It only can be replaced as an identical

paired set specific for each counterweight.*

*Refer to the latest revision of Service Instruction Nos. SI-1012 and SI-1535 for part numbers and

instructions to replace counterweights and rollers.