IO-390-D Series Engine Maintenance Manual

12-30

© 2020 Avco Corporation. All Rights Reserved

Page 88

March 2020

IO-390-D Series Engine Maintenance Manual

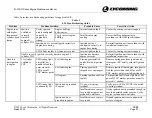

Table 1 (Cont.)

Fault Isolation Guide

Problem

Cause

Corrective Action

Ref.

Low fuel flow

(Cont.)

Fuel line to fuel flow

gage is broken, loose, or

blocked

Look for fuel dye stains to identify

leaky, cracked, damaged or loose fuel

lines. Replace any cracked or damaged

fuel line. Refer to the “Fuel Line

Replacement” procedure.

To identify a blocked fuel line,

disconnect the line at both ends and

blow it out with compressed air. Re-

connect the fuel line. Torque as per the

latest revision of the

Service Table of

Limits SSP-1776

. Make sure the fuel

line is no longer blocked.

73-10

Low fuel pressure

1.

Examine the fuel filter for plugs;

replace a plugged fuel filter as per

the aircraft manufacturer’s

instructions.

2.

Adjust the fuel pressure in

accordance with the aircraft

manufacturer’s instructions.

3.

Replace the fuel pump* or fuel

pressure regulator. Refer to the “Fuel

Pump Replacement” procedure.

AMM

73-10

Engine will not turn

static rpm or will not

develop rated rpm

Decreased air flow in the

induction system

1.

Make sure that the air filters are clean.

2.

Complete the “Induction System

Inspection” and remove all blockages.

3.

Make sure that the air box is installed

in accordance with the airframe

manufacturer's specifications.

4.

Repair or replace the air inlet or

manifold if necessary.

72-80

AMM

Blockage in air inlet or

manifold

Air filter dirty

Replace the air filter.

NOTICE:

Occasionally new air filters

will have an excessive air drop through

them. If this condition is suspected,

remove the air filter and operate the

engine to full power on a hard surface

in a dust-free area.

AMM

* Review any applicable warranty information relative to replacement of a fuel component as per the

latest revision of Service Letters L221 and L253.