IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

74-30

March 2020

Page 283

IO-390-D Series Engine Maintenance Manual

(b)

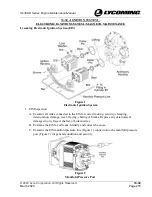

Ground the EIS to the negative (-) lead of the temporary power source. Do not

attempt to ground through painted or anodized surfaces – ground through the

machined mount face, p-lead shield terminal (Figure 7) or case bolt heads.

(c)

The EIS LED (Figure 7) should illuminate green. If not, wiggle the drive gear, re-

ground the EIS and ensure the EIS p-lead terminal (Figure 7) is not grounded.

NOTICE:

The EIS LED will not turn on if the p-lead terminal is grounded.

(d)

Slowly rotate the EIS drive gear to find the point where the LED goes off.

(e)

TURN SLOWLY – the LED alignment point has a ½° window and is difficult

to see if turning fast!

(f)

The point at which the LED goes off is the EIS’s internal TDC alignment.

(g)

Once this point is found, care should be taken to avoid any rotation of the

EIS drive gear during further steps of engine installation.

(3)

Mount the EIS on the Engine:

CAUTION

LYCOMING EIS UNITS ARE PROPRIETARY TO

LYCOMING. USE ONLY APPROVED DOCUMENTATION

SUPPLIED BY LYCOMING FOR THE INSTALLATION AND

CONTINUED AIRWORTHINESS OF LYCOMING EIS UNITS.

NOTE:

UNLIKE A MAGNETO, THE LYCOMING EIS IS TIMED

(SYNCED) TO #1 CYLINDER COMPRESSION STROKE TDC (0°).

NOTICE:

The EIS operates by syncing its internal TDC alignment point to #1-cylinder

compression stroke (TDC – 0°).

(a)

Confirm the engine is at top dead center (TDC - 0°) of #1 cylinder on the

compression stoke.

(b)

Ensure the O-ring is present, free of debris and seated in the EIS face groove.

(c)

Apply Lubrico

®

M-6 grease or equivalent to the mating surface of the EIS flange

and the O-ring.

(d)

Ensure the EIS is still internally timed as described in the “Internally Time the

EIS” section.

(e)

Without allowing the EIS drive gear to rotate,

align the EIS mounting ear slots

with the engine studs and slide the EIS into the magneto cavity.

(f)

Hold the EIS flush to the engine, clock the EIS to ensure the point when the LED

goes off is within the rotational sweep limits of the mounting ear slots.

(g)

Repeat steps (d) through (f) above if unable to find the point when the LED goes

off as the EIS drive gear may have skipped a tooth over the engine gear when

pushed in.

(h)

If

still unable

to find the point when the LED goes off, reinstall the drive gear to

the alternate drive gear orientation as described in the “Install the Drive Gear

(Magneto Gear)” section in this chapter.