IO-390-D Series Engine Maintenance Manual

72-20

© 2020 Avco Corporation. All Rights Reserved

Page 140

March 2020

IO-390-D Series Engine Maintenance Manual

6.

Crankshaft Inspection

A.

Before cleaning the crankshaft, initially examine the crankshaft gear and crankshaft inner

diameter and external surface for evidence of pitting and wear. These conditions are of

particular importance when they occur on the involutes of the crankshaft gear teeth. Replace

the crankshaft gear if there is any pitting or wear.

B.

Clean the crankshaft per “Crankshaft Cleaning” and “Crankshaft Counterbore Cleaning”

procedures in Chapter 05-30. Prior to inspection, the crankshaft counterbore must be clean,

dry, and free of debris. Make a copy of the Crankshaft Inspection Checklist to record the

condition of the crankshaft and any corrective action.

C.

Continue with the crankshaft inspection. Do not make scores, scratches, or etch markings of

any kind on the crankshaft. A mark in any of these areas can cause the crankshaft to weaken

and to possibly fail.

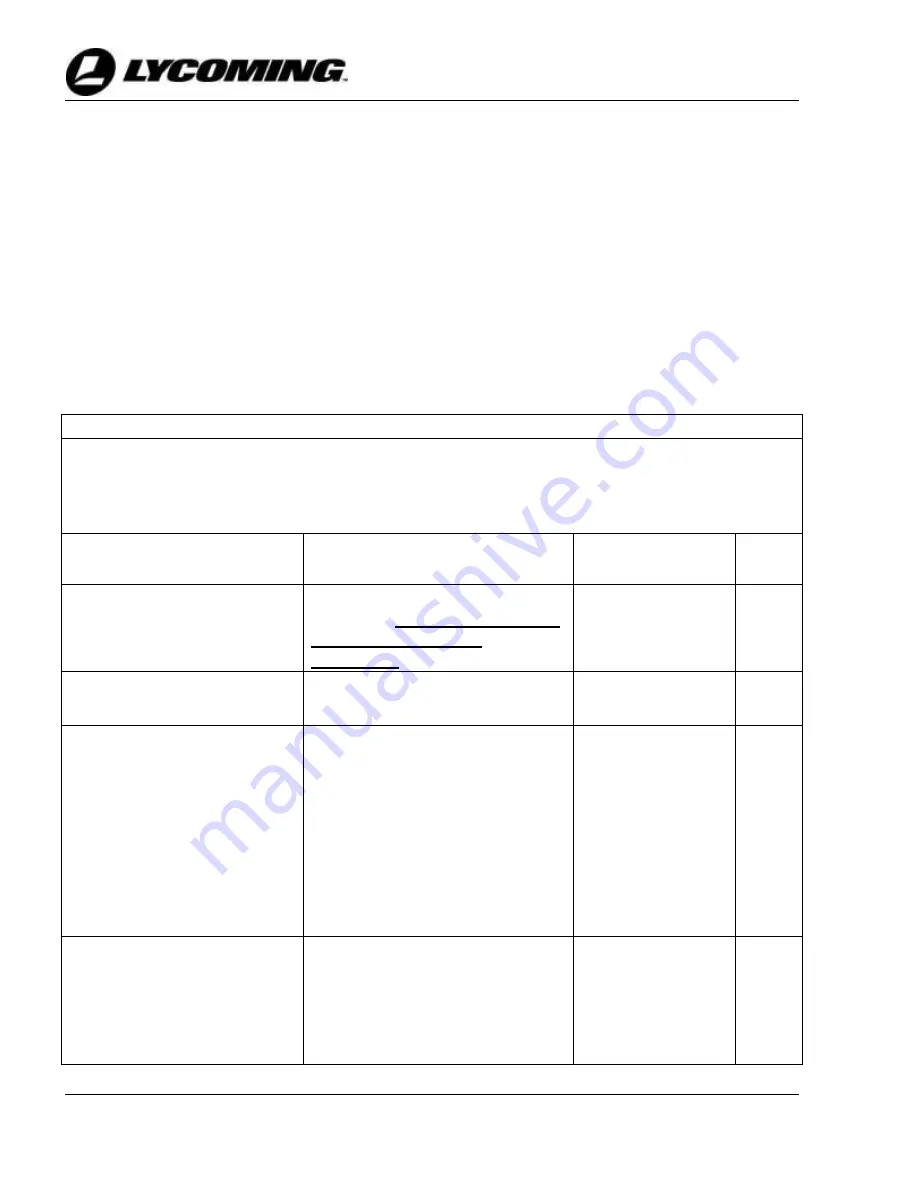

Crankshaft Inspection Checklist for IO-390-D Series Engines

Engine Model Number__________________ Engine Serial Number:__________________

Engine Time:______________________ Date Inspection Done: _____________________

Inspection done by:______________________________

Item

Comments

Findings/

Corrective Action

Done

Carefully examine all surfaces

of the crankshaft for cracks,

gouges, nicks, dents, or

damage.

If a crack is found, replace the

crankshaft.

Do NOT try to repair

a cracked or damaged

crankshaft.

Acceptable

Replace

Complete a magnetic particle

inspection on the crankshaft.

Refer to the “Non-Destructive

Testing” section in Chapter 05-50.

Acceptable

Replace

Use a flashlight, magnifying

glass, and angled inspection

mirror to visually examine the

inner diameter of the crankshaft

bore (Figure 24), starting at the

crankshaft flange end. Look for

pit marks and corrosion.

"Pitting" looks like holes,

cracks, or fissures of

unspecified depth or direction.

If corrosion is found, replace the

crankshaft.

If pitting is found, complete a

Fluorescent Penetrant Inspection

(FPI) (per the section "Non-

Destructive Testing" in Chapter

05-50).

Acceptable

Replace

Measure the inner diameter of

the crankshaft. Record the

measurement. Refer to Figure

24.

For a crankshaft to be acceptable,

the inner diameter must not be

more than 1.910 in. (4.851 cm). If

the inner diameter of the

crankshaft is more than 1.910 in.

(4.851 cm), replace the crankshaft.

Inner diameter

measurement:

_______ inches

or

______ centimeters