IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

12-30

March 2020

Page 87

IO-390-D Series Engine Maintenance Manual

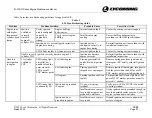

Table 1 (Cont.)

Fault Isolation Guide

Problem

Cause

Corrective Action

Ref.

High fuel flow

Blocked injection

nozzles evident by high

flow reading on pressure

type fuel flow indicator

1.

Complete an “Injection Nozzle Fuel

Flow-Check.”

2.

Complete the “Injection Nozzle

Removal” procedure.

3.

Complete the “Injection Nozzle

Cleaning” procedure.

4.

Complete the “Injection Nozzle

Installation” procedure.

73-10

5-30

73-10

Broken flow gage

Install the master fuel flow gage and

operate the engine to compare gages.

or

Replace the non-conforming fuel flow

gage.

Fuel injector rich

Remove the fuel injector. Either send it

to a manufacturer-approved repair

facility or replace it as per the “Fuel

Injector Replacement” procedure.*

73-10

Low fuel flow

Dirty fuel pump filter

Remove and clean the fuel pump filter

with acetone or MEK, blow out with

compressed air, and re-install the fuel

pump filter

or

Replace the fuel pump filter.

AMM

Faulty fuel flow gage

1.

Install the master fuel flow gage and

operate the engine to compare gages.

2.

Replace a damaged fuel flow gage.

AMM

Fuel manifold does not

open all the way at times.

1.

Complete the “Fuel Manifold

Removal” procedure.*

2.

Send to Lycoming Engines or an

authorized repair facility.

3.

Complete the “Fuel Manifold

Installation” procedure.

73-10

* Review any applicable warranty information relative to replacement of a fuel component as per the

latest revision of Service Letters L221 and L253.