IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-20

March 2020

Page 175

IO-390-D Series Engine Maintenance Manual

A.

Assemble the Crankcase Halves

CAUTION

THE CRANKCASE HALVES ARE A MATCHED SET, IF ONE HALF IS

CRACKED OR DAMAGED BOTH HALVES MUST BE REPLACED.

ONLY LYCOMING-APPROVED SEALANTS ARE TO BE USED

DURING CRANKCASE ASSEMBLY. USE OF ANY OTHER NON-

APPROVED SEALANT COULD RESULT IN A LOSS OF CLAMPING

FORCE AND/OR TORQUE.

IN THE NEXT STEP, DO NOT GET THE GASKET COMPOUND IN THE

BORE OF THE NOSE SEAL OR IN ANY CRANKCASE BORE. IF ANY

NON-HARDENING GASKET COMPOUND GETS INTO THE NOSE

SEAL BORE OR ANY CRANKCASE BORE, CAREFULLY REMOVE

THE GASKET COMPOUND WITH A SOFT CLOTH AND SOLVENT

(ACETONE, MEK, OR EQUIVALENT). DO NOT GET MEK ON THE

CRANKSHAFT OIL SEAL.

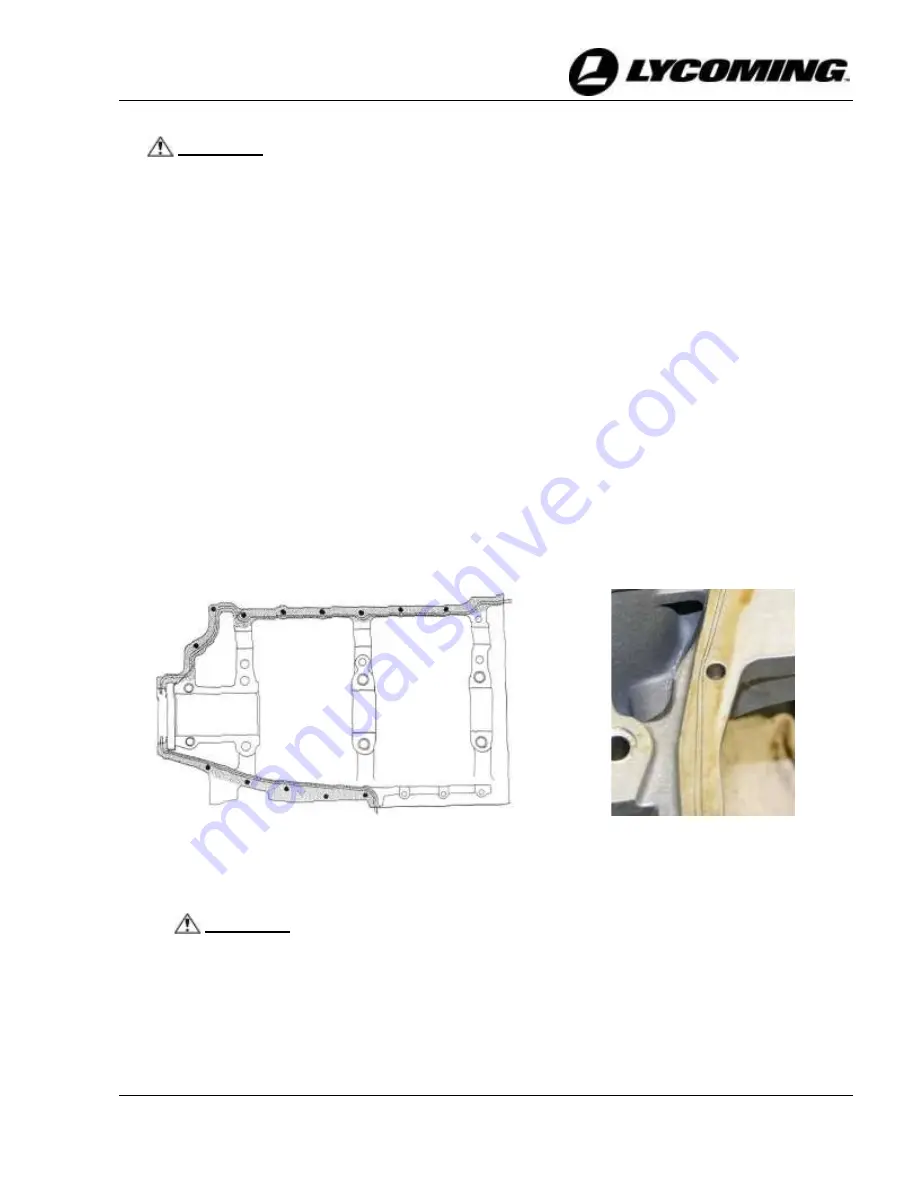

(1)

Apply a thin layer of non-hardening gasket material such as POB #4 Perfect Seal gasket

compound or equivalent to the outside mating surface of only one crankcase half (darker

area shown in Figure 82.)

(2)

Measure and cut a total of four continuous lengths of "00" silk threads (four for only one

crankcase half). Two of the lengths will extend along the entire length of the top of the

crankcase flange as shown in Figure 82, and two silk thread lengths will be shorter to

cover the distance shown on the bottom flange of the same crankcase half. Do not apply

silk thread pairs to both crankcase halves.

Figure 82

Area on the Crankcase Flange to Apply

the POB Sealant and Silk Thread

Figure 83

Placement of Silk Threads

AlongInside Edge of

Crankcase Flange

CAUTION

TO ENSURE CORRECT SEALING, MAKE SURE THE SILK

THREADS RUN THE LENGTH, AS A CONTINUOUS PIECE, OF

THE INSIDE OF THE CRANKCASE FLANGE (FIGURE 82) AND

THERE ARE NO BREAKS IN THE ANY OF THE THREADS.

BREAKS IN THE SILK THREAD CAN CAUSE THE CRANKCASE

TO LEAK. MAKE SURE THE THREADS DO NOT CROSS OVER OR

LAY OVER EACH OTHER (FIGURE 82) OR COVER A HOLE IN

THE CRANKCASE FLANGE.