IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

73-10

March 2020

Page 265

IO-390-D Series Engine Maintenance Manual

B.

Fuel Injector Installation

(1)

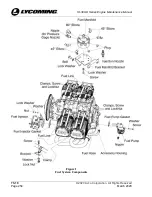

Align the fuel injector on the engine with a new gasket (Figure 8).

Figure 8

Fuel Injector

(2)

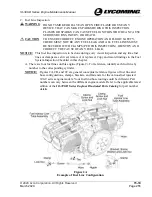

Install four nuts, each with a washer and a new lock washer hand tight. Refer to Figure 9

for the torque sequence for the two different size nuts that can be used:

For 1/4-20 size nuts:

Figure 9

Crisscross Pattern of

Nut Torquing

For 5/16-18 size nuts:

(a)

Torque the nuts in

crisscross pattern (Figure 9)

to an initial torque of 48 in.-

lb. (5 Nm).

(a)

Torque the nuts in

crisscross pattern (Figure

9) to an initial torque of

90 in.-lb. (10 Nm).

(b)

Torque the four nuts again

in the same crisscross

pattern to a final maximum

torque of 96 in.-lb. (11

Nm).

(b)

Torque the four nuts

again in the same

crisscross pattern to a

final maximum torque of

204 in.-lb. (23 Nm).

(3)

During the “Operational Ground Check” in Chapter 72-00 (which is to be done after all

maintenance is complete), look for fuel leaks at the fuel lines and connections during

engine operation. Identify and correct the cause of any fuel leak. There must not be any

fuel leaks when the engine is returned to service.

6.

Injection Nozzle Replacement

WARNING

DO NOT SMOKE OR HAVE AN OPEN FIRE FLAME OR USE ANY

DEVICE THAT CAN MAKE SPARKS. FLAMES OR SPARKS CAN CAUSE

FUEL IGNITION WHICH CAN CAUSE SERIOUS BURNS, INJURY OR

DEATH.

NOTICE

: If this injection nozzle replacement procedure is completed with the engine installed in

the airframe, refer to the airframe manufacturer’s instructions for shutting off the fuel

and grounding the aircraft.