IO-390-D Series Engine Maintenance Manual

74-30

© 2020 Avco Corporation. All Rights Reserved

Page 288

March 2020

IO-390-D Series Engine Maintenance Manual

4.

Magneto Replacement Procedure

WARNING

BEFORE THIS PROCEDURE, MAKE SURE ALL POWER IS DISABLED

TO THE ENGINE TO PREVENT ELECTRICAL SHOCK AND INJUIRY.

A.

Magneto Removal

(1)

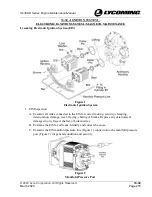

Disconnect the harness (Figure

11) from the magneto to be

removed.

(2)

Hold the magneto and remove

the two nuts, two lock washers

and two clamps from the

magneto. Discard the lock

washers.

(3)

Remove the magneto.

(4)

Remove and discard the

gasket.

Figure 11

Magnetos

B.

Magneto Installation

NOTICE:

This procedure applies to Slick magnetos only. Refer to the manufacturer’s

instructions for other types of magnetos.

Make sure the correct magneto is installed on the corresponding side of the

engine.

A new or serviceable magneto, new magneto gasket, and two new lock washers are necessary

to install the magneto. Refer to the applicable parts catalog.

(1)

Apply a light coat of C5-A Copper-Based

Anti-Seize compound to the tapered section

of the magneto driveshaft (Figure 12).

(2)

Install the magneto gear or impulse coupling

(whichever is applicable) on the magneto

driveshaft.

(3)

Remove excess anti-seize compound from

the magneto driveshaft.

(4)

Install the gear nut on the magneto drive

shaft. Torque the gear nut per the magneto

manufacturer’s instructions.

(5)

Install a new cotter pin through the nut and

magneto driveshaft. Bend the top prong on

the cotter pin over the driveshaft and bend

the bottom prong of the cotter pin down.

Figure 12

Anti-Seize Application

(6)

Verify the magneto direction of rotation as per the magneto data plate.