IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

12-30

March 2020

Page 93

IO-390-D Series Engine Maintenance Manual

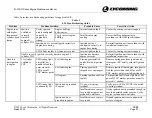

Table 1 (Cont.)

Fault Isolation Guide

Problem

Cause

Corrective Action

Ref.

Low oil pressure

(Cont.)

Failed or failing

bearings

NOTICE:

Metal in the

oil filter element or oil

suction screen is a sign

of excessive bearing

wear.

Drain the oil from the oil sump.

Open the crankcase and examine the

bearings. Refer to “Tappet, Main

Bearing, and O-Ring Removal”

or

It is recommended the engine be sent

to Lycoming Engines for evaluation.

Include a description of the problem.

12-10

72-05

72-20

Oil pump not operating

correctly

Remove and examine the oil pump.

72-25

Oil pressure gage not

operating correctly

Test the oil pressure gage.

AMM

Excessive oil

consumption

New piston rings are not

completely seated

(break-in not done).

As part of break-in, operate the engine

at not less than 65% power for the first

50 hours.

IOM

Piston rings are worn,

broken, or incorrectly

installed

OR

Cylinder barrels are

glazed or worn too

much

1.

Complete the “Cylinder

Compression Check Procedure.”

2.

Complete the “Cylinder Borescope

Inspection Procedure” to determine

if further corrective action is

necessary

NOTICE:

Listen for a hissing sound

at the breather of the crankcase which

is an indication of air leaks around the

rings.

72-30

3.

Remove the cylinders, hone the

cylinder barrels, replace the piston

rings, and re-install the cylinders as

per the following sections:

•

Cylinder Removal

•

Piston Removal

•

Piston Inspection

•

Piston Ring Replacement

•

Barrel Glaze and Varnish

Removal from Interior Cylinder

Barrel

•

Piston Installation

•

Cylinder Installation

72-30