IO-390-D Series Engine Maintenance Manual

73-10

© 2020 Avco Corporation. All Rights Reserved

Page 260

March 2020

IO-390-D Series Engine Maintenance Manual

Fuel System Inspection Checklist (Cont.)

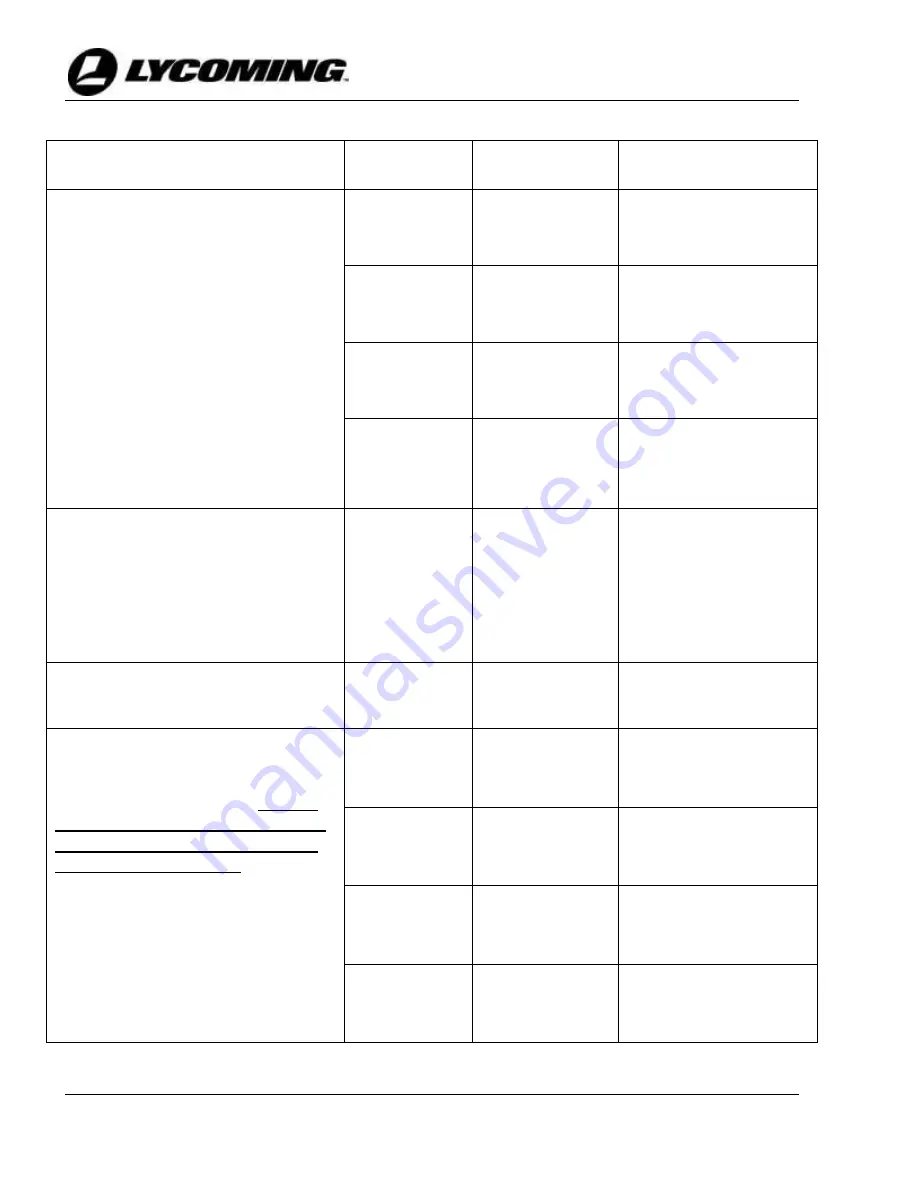

Inspection Item

Fuel Line or

Injection Nozzle

Findings

Corrective Action

Taken

Examine each fuel line for damage,

leaks, nicks, crimps, kinks, sharp

bends, stains (from fuel leaks), cracks,

brittleness, chafing, and looseness.

Replace (do not try to repair) a worn,

damaged, leaky, chafed, brittle,

crimped, kinked, bent, or loose fuel

line.

Make sure no fuel lines touch the

engine or aircraft baffle hardware.

There must be a minimum clearance

of 3/16 in. (4.76 mm) between a fuel

line and any engine or aircraft surface.

In general, make sure fuel lines do not

touch heat sources.

1

2

3

4

Make sure the mixture control and

throttle linkage have full travel,

freedom of movement.

Correct the mixture control and

throttle linkage limited travel or

restricted movement per the aircraft

manufacturer’s instructions.

N/A

Lubricate the linkage per the aircraft

manufacturer's instruction.

N/A

Make sure each fuel line is held in

place securely using clamps with

cushions to prevent fuel line

movement due to vibration.

If a fuel

line had been in service and clamps

were not installed, replace the fuel

line with a new fuel line.

Make sure clamps are securely

attached. If the clamps are loose,

replace the fuel line. Install new

clamps that attach the line securely.

On engines that use metal clamps with

no cushion, install a fuel line sleeve at

each of those clamping locations.

1

2

3

4