IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-20

March 2020

Page 131

IO-390-D Series Engine Maintenance Manual

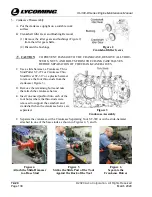

G.

Remove the camshaft when the crankcase halves are separated enough to allow for removal

(Figure 7).

H.

Remove the camshaft tachometer shaft, spacer, pin, and internal retaining ring. Discard the

internal retaining ring, spacer, and pin.

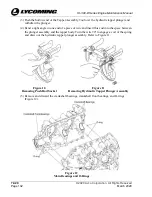

I.

Continue separating the crankcase halves until the crankshaft can be removed from the

crankcase (Figure 8).

Figure 7

Remove the Camshaft

Figure 8

Remove the Crankshaft

J.

Put the crankshaft in a suitable V-block-

type fixture as shown in Figure 9.

NOTICE:

Undersize crankshafts are

identified by a code symbol

stamped on the front of the

flange as a suffix to the part

number. In addition to the code

symbols, the letters "RN" are

stamped as a suffix to the

crankshaft serial number,

indicating that the crankshaft

has been renitrided.

Figure 9

Crankshaft in V-Block-Type Fixture

K.

Tappet, Main Bearing and O-Ring Removal

(1)

Remove the hydraulic tappet plungers using the Tappet Assembly Tool P/N 64941.

CAUTION

IF A TAPPET ASSEMBLY TOOL IS NOT AVAILABLE, REMOVE

THE PUSH ROD SOCKETS BY HAND OR BY MAKING A LOOP

FROM A SHORT LENGTH OF SAFETY WIRE. DO NOT USE A

MAGNET TO REMOVE THE SOCKET OR THE PLUNGER

ASSEMBLY FROM THE ENGINE, AS THIS COULD CAUSE THE

BALL TO REMAIN OFF ITS SEAT AND MAKE THE UNIT

INOPERATIVE.

(2)

Remove the push rod socket (Figure 10) by placing heavy grease on the ball end of the

Tappet Assembly Tool. Push the greased ball end of the Tappet Assembly Tool into the

socket and withdraw it. The socket will adhere to the grease.